SIEGMUND

Welding Table

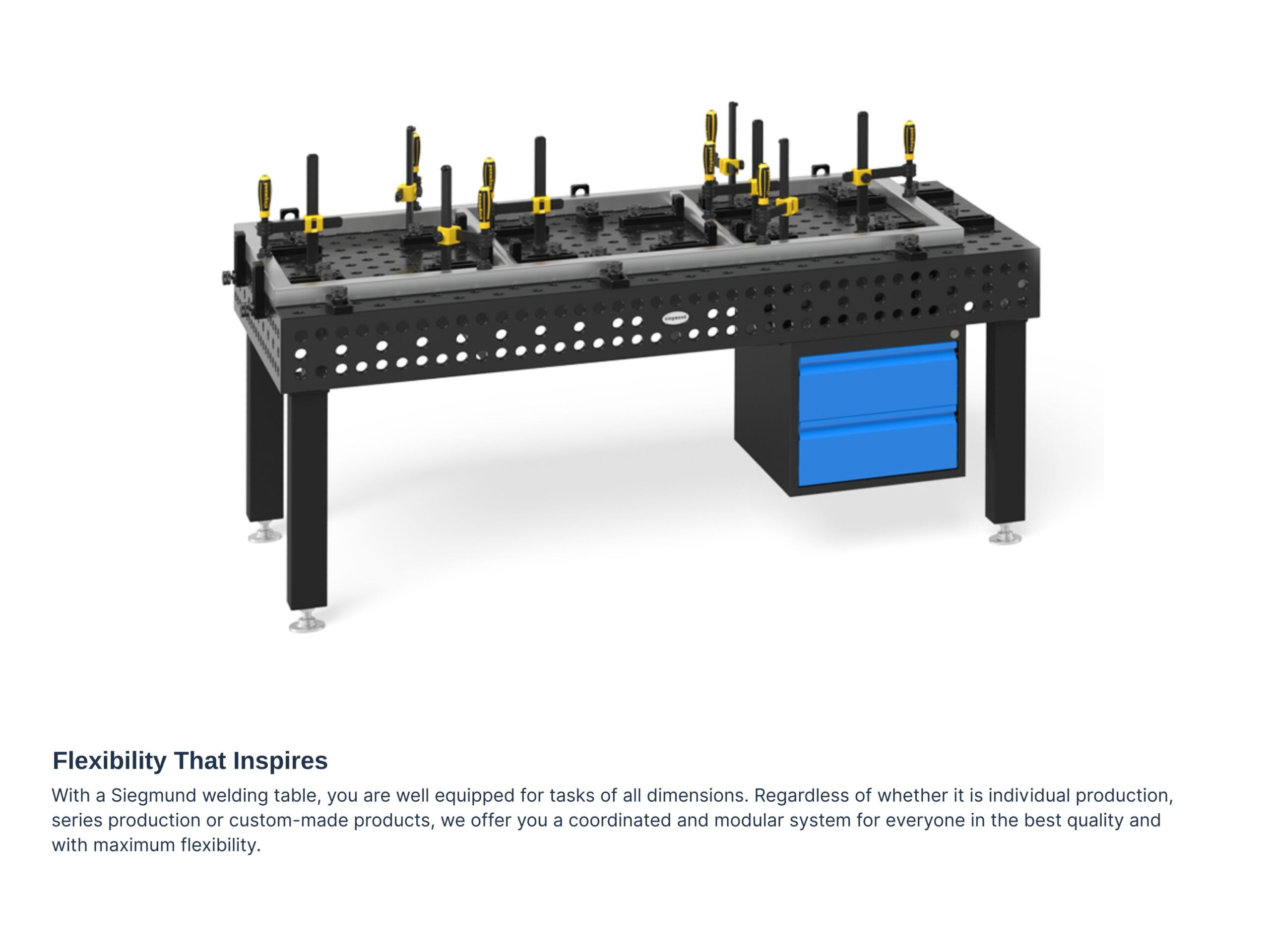

At MPAC, we offer Siegmund Welding and Clamping tables built for professionals who demand precision, durability and efficiency. Designed for welding and assembly they feature a precision borehole system for flexible, repeatable setups. The result: faster workflows, less rework and reliable high load performance, ideal for complex builds and high volume production.

Precision

Laser gridlines

Repeatable setups

Chamfered holes

Durability

X8 tool steel

Plasma nitrided

Anti spatter coat

Stability

25mm tabletop

Reinforced ribs

Vibration free

Performance

2000kg load

Modular system

3D clamping

Table Features in Detail

Surface

-

Precisely milled surface

-

Plasma nitrided and BAR coated: low wear, durable, corrosion resistant and easily maintained

-

Significantly less welding spatter adhesion

Radiused Boreholes

-

Easier insertion of bolts and accessories

-

Less adherence of welding spatters on bore edges

-

Less damage to the borehole edges

Grid Lines

-

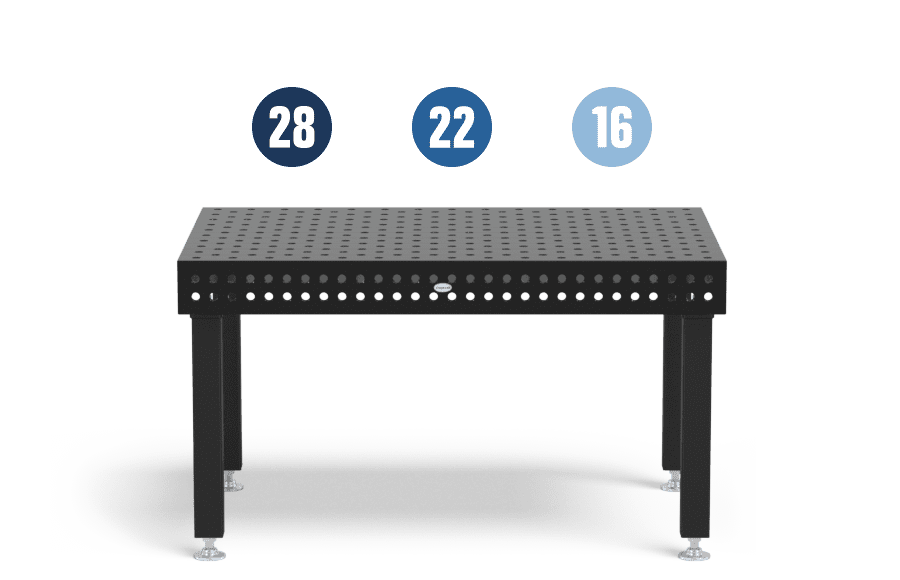

Continuous lines for better orientation at a distance of 50 mm (System 16) or 100 mm (System 22 and 28)

-

Enable precise clamping

Scale

-

Scaling on all four sides

-

Saves time when clamping and setting up

Elaborate Radiuses

-

Radiused edges and corners

-

Reduce the risk of injury

-

Protect components and accessories from getting damaged

Table Side Panel

-

Additional clamping surface

-

For extending and connecting tables

Ribbing

-

For optimum stability and rigidity of the table top

-

For all table series and sizes

Stable Table Legs

-

Optimal pressure distribution

-

High strength ensures precision of the table surface

-

Different versions available

Extreme Durability Tested

System Comparison

Compare the different Siegmund welding table systems, focusing on key features, performance and how each system fits specific welding and fabrication needs.

Materials Comparison

Dive into the various material options available, understanding their strengths, durability and best use cases for your projects.