SIEGMUND

Welding Cell

Revolutionise your welding operations with the Siegmund Welding Cell available at MPAC, designed to integrate robotics into your workflow. Combining innovative clamping technology and modular design, it simplifies automation and series production, while offering compatibility with all robots and cobots.

EFFICIENCY

Quick setup

Automated welding

Flexible design

PRECISION

Zero point clamping

Modular system

Consistent results

USABILITY

Robot ready

Easy integration

Low start up cost

SAFETY

High security

Weld protection

Radiation shield

Product Selection

A Modular System Tailored To Your Needs

Configure a welding cell to fit your Siegmund welding table, with doors and walls positioned as desired.

Maximise Efficiency with Perfect Interaction

Benefit from a combination of Siegmund expertise in, a welding cell with zero point clamping, perforated plates and a new clamping system.

✔ Create small and large series fixtures with the Siegmund clamping system

✔ Reuse fixtures on the perforated plate

✔ Start the welding process with the robot

✔ Quickly swap perforated plates with a precise fit using zero point clamping

✔ Protect users from weld spatter and radiation

Clamping System

For the simple creation of series fixtures with templates.

Zero Point Clamping System

Simplified resetting for new fixtures and perforated plates.

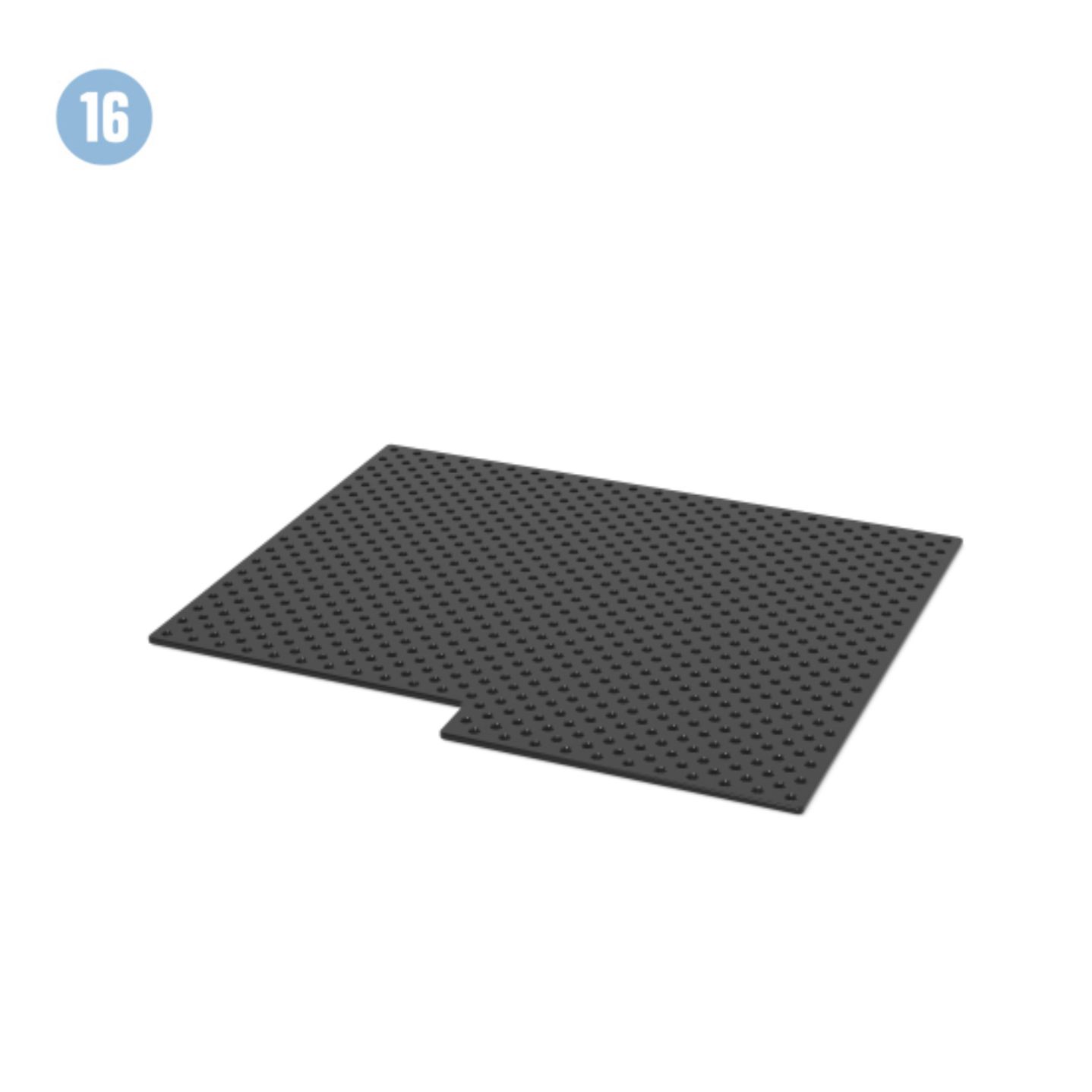

Perforated Plates

We recommend Siegmund perforated plates, welding or slot tables as a base.

Perforated Plates for Siegmund Welding Cell

Some perforated plates have recesses for the robot console, optimised for use in the Siegmund welding cell. Combined with the zero point clamping system and new clamping system, setup times in automation and series production are reduced.

Perforated plate X8.7 950x800x12 diagonal grid plasma nitrided

Perforated plate X8.7 1150x1000x12 diagonal grid plasma nitrided

Perforated plate X8.7 1450x1150x12 diagonal grid plasma nitrided

Special Table for Siegmund Welding Cell

✔ Borehole grid for fastening components (welding cell, partition wall, console etc)

✔ Ventilation opening for anti swirl extraction

✔ Optimal downward coverage

✔ Cable trunking below the table

✔ Available sizes: 2000 x 1000 mm, 2400 x 1200 mm, 3000 x 1500 mm

✔ Borehole Ø 16 mm

✔ Material thickness approx 11.5 – 13 mm

✔ Premium steel S355J2+N + plasma nitration

Compatibility with standard Siegmund welding tables:

The welding cell is also available with standard Siegmund welding tables (2000×1000 mm, 2400×1200 mm, 3000×1500 mm) for an additional cost. When using standard Siegmund welding tables, we recommend closing some boreholes with cover caps (Item No. 160238.10 and 280238.10) to avoid unwanted air circulation during welding.