SIEGMUND

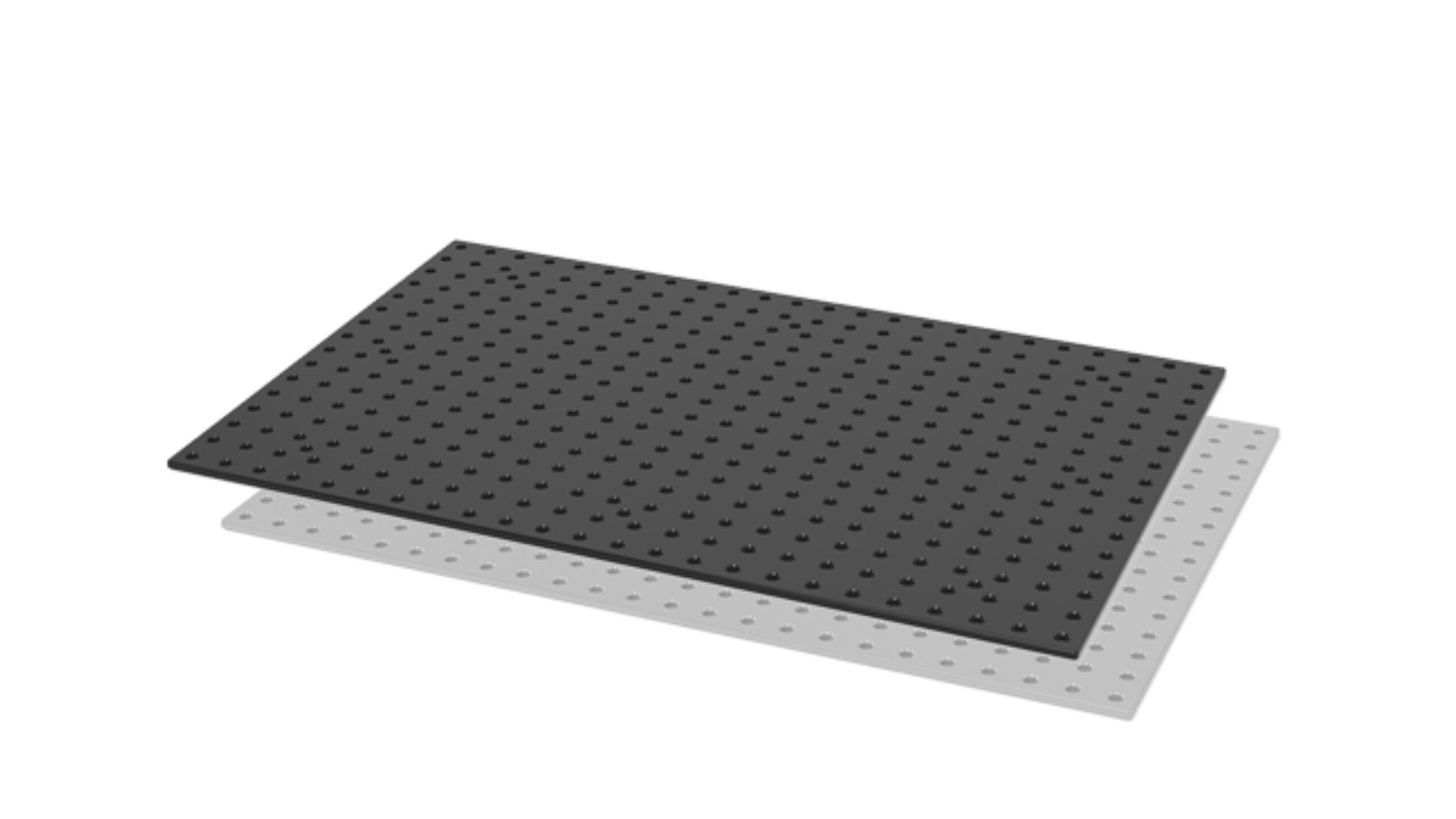

PERforated Plates

MPAC supplies Siegmund Perforated Plates, durable, accurate and built for high performance setups. With multiple borehole systems, nitrided surfaces and full tool compatibility, they form the perfect base for welding, clamping and assembly across all industries.

Strength

Nitrided finish

High load rating

Spatter resistant

Precision

16–28 mm bores

Grid aligned holes

Up to 850 HV

Compatibility

Tooling ready

Fits all tables

Multi size range

Materials

Tool steel X8.7

Steel S355J2+N

Stainless options

Suitable Products

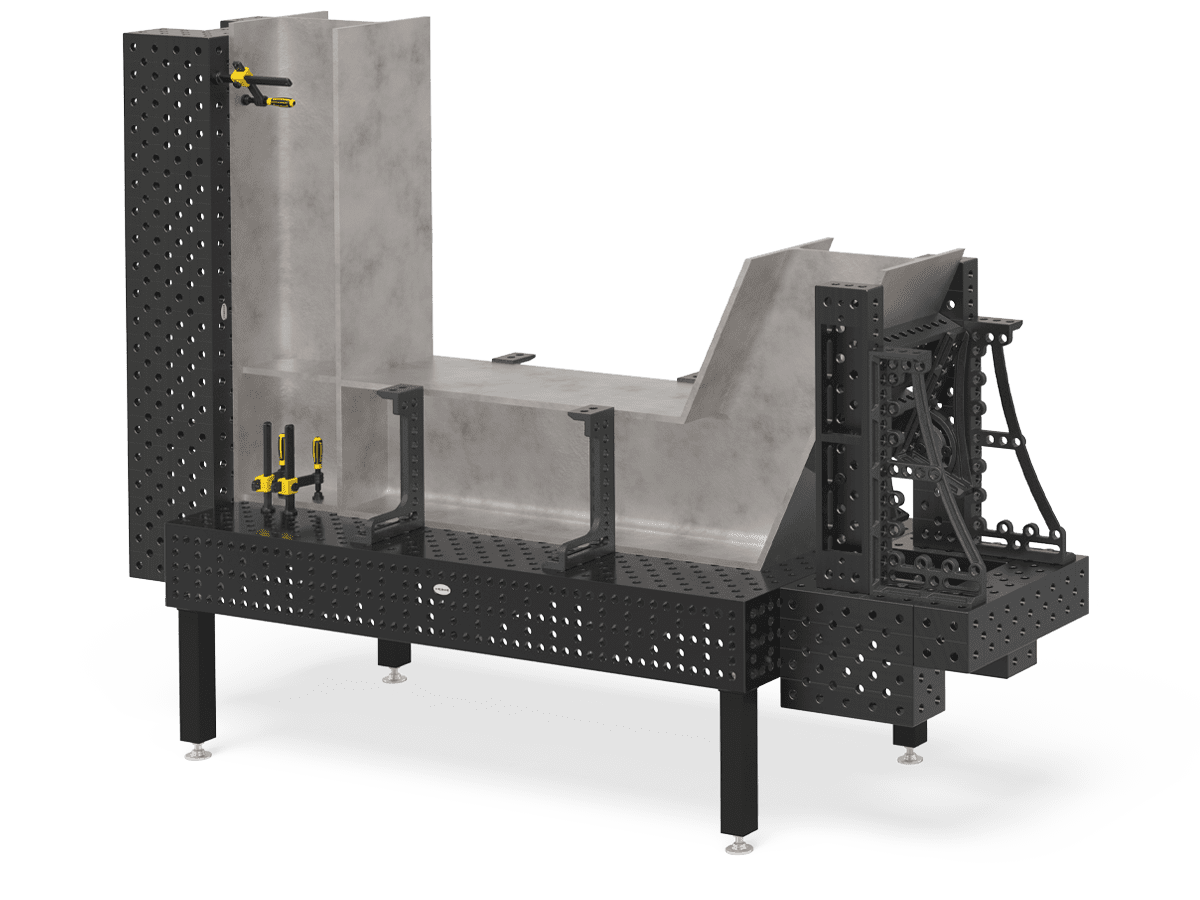

Workstation

The all rounder in every workshop

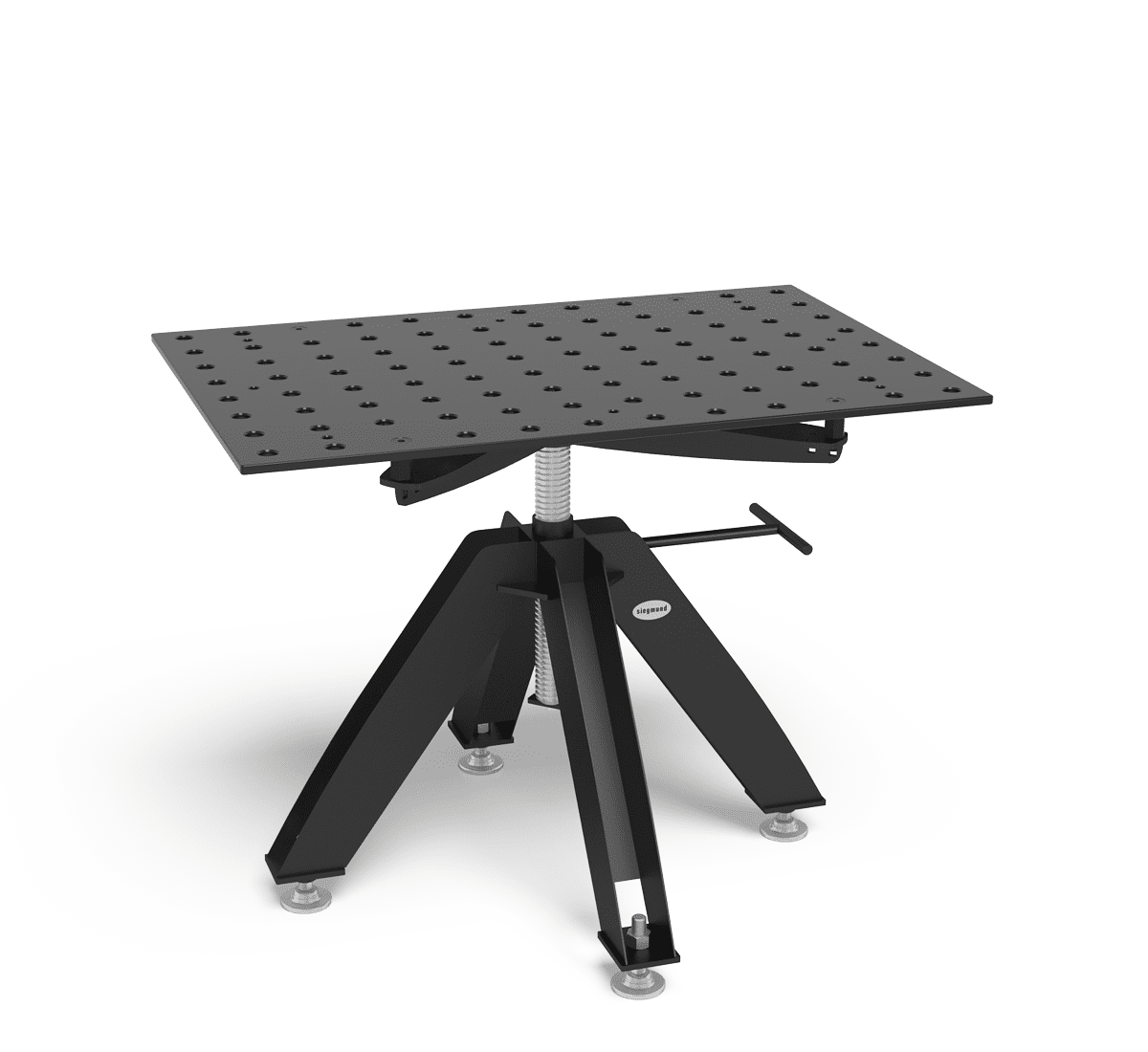

Rotating Table

Easy adjustment for ideal working height

Lifting Table

Ergonomic pain free working

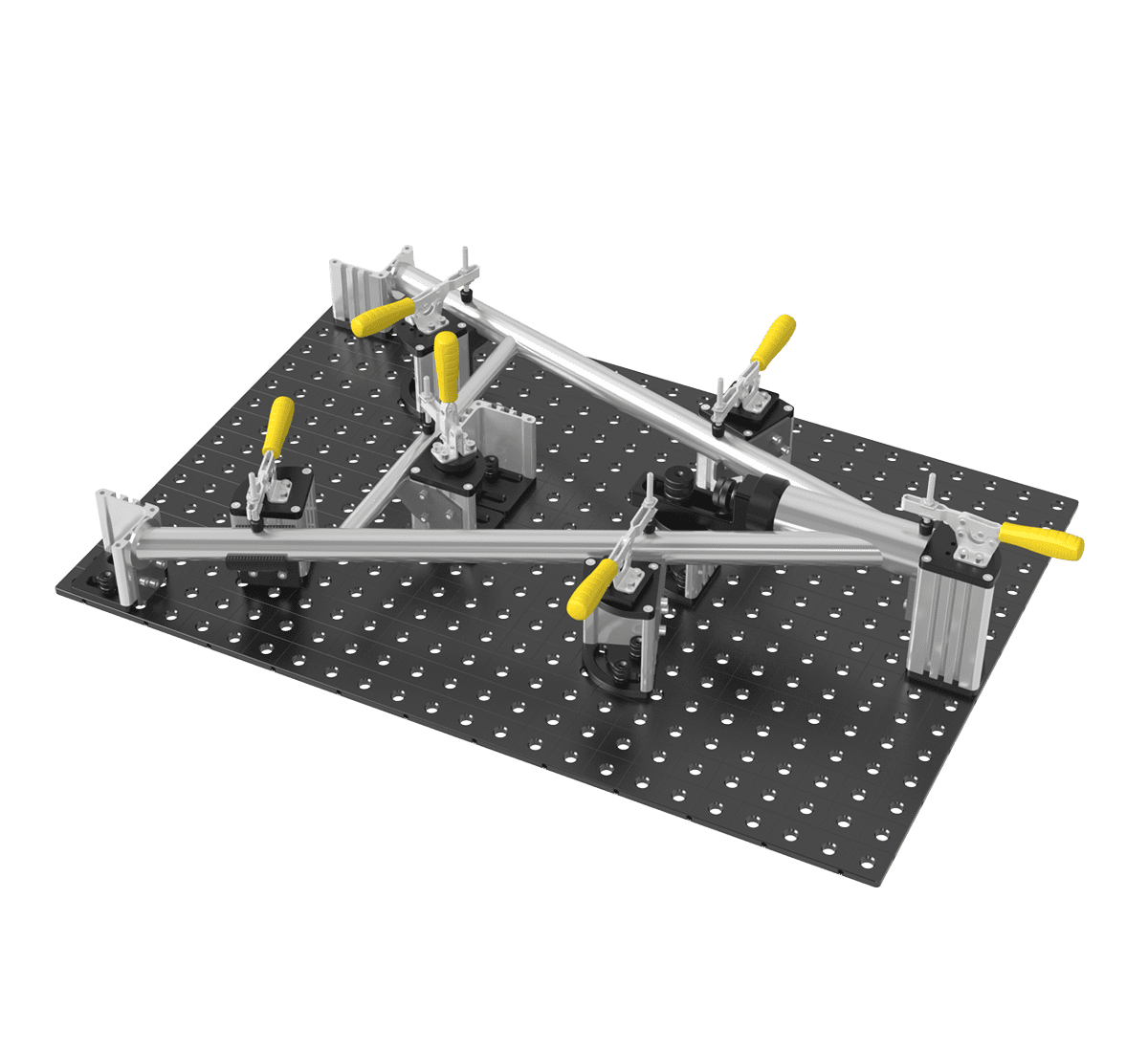

Clamping System

For creating series fixtures with templates

System Comparison

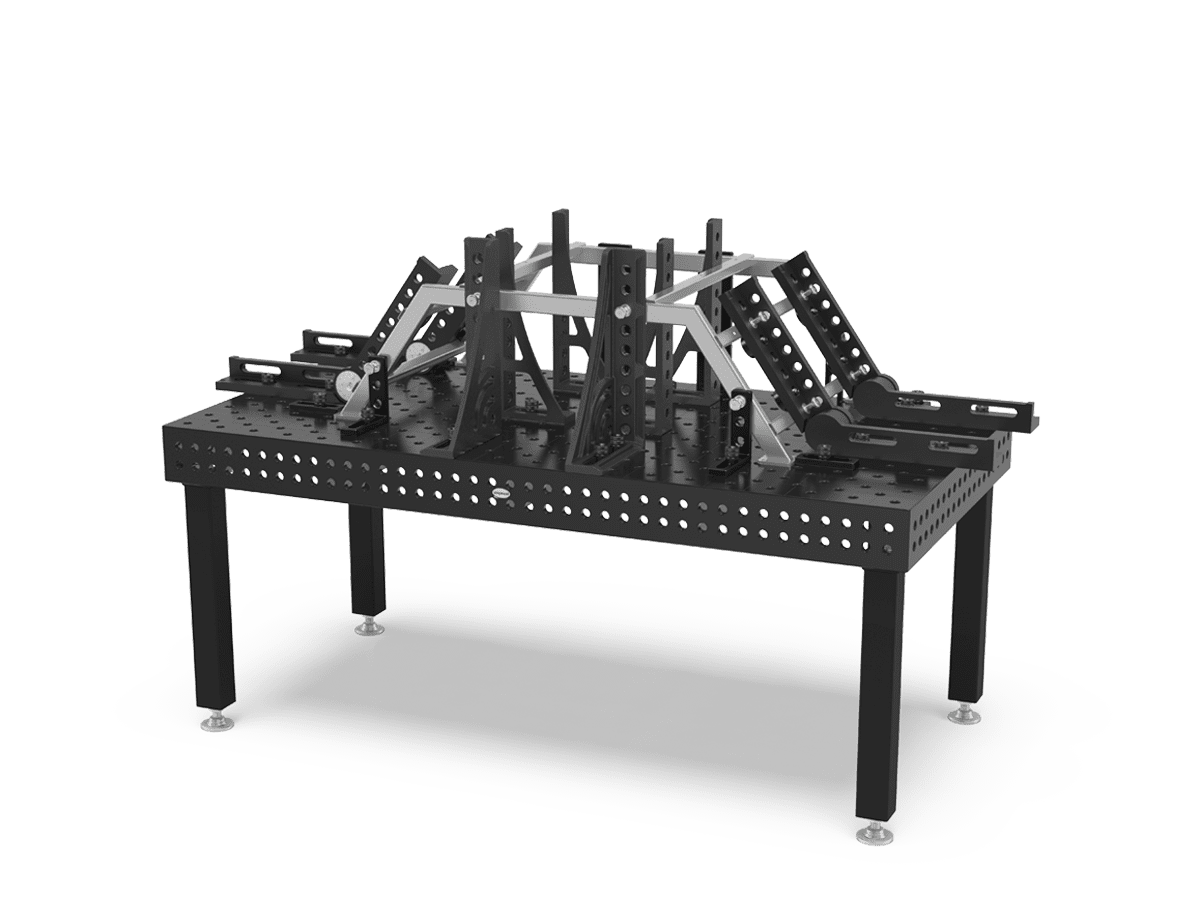

SYSTEM 28

Details

- Borehole Ø 28 mm

- Material thickness approx 24,5 – 27 mm

- Boreholes on the surface in diagonal grid or 100×100 mm grid

- Boreholes with radius 3 mm

- Height of table side 200 mm / 300 mm

- Recommended load up to 6000 kg*

max 2000 kg per leg basic equipment

max 3000 kg per leg basic equipment PLUS

Our largest system is ideal for light to heavy workpieces due to its high resilience and rigidity. The solid clamping devices also keep large components in shape and prevent distortion when welding the individual assemblies.

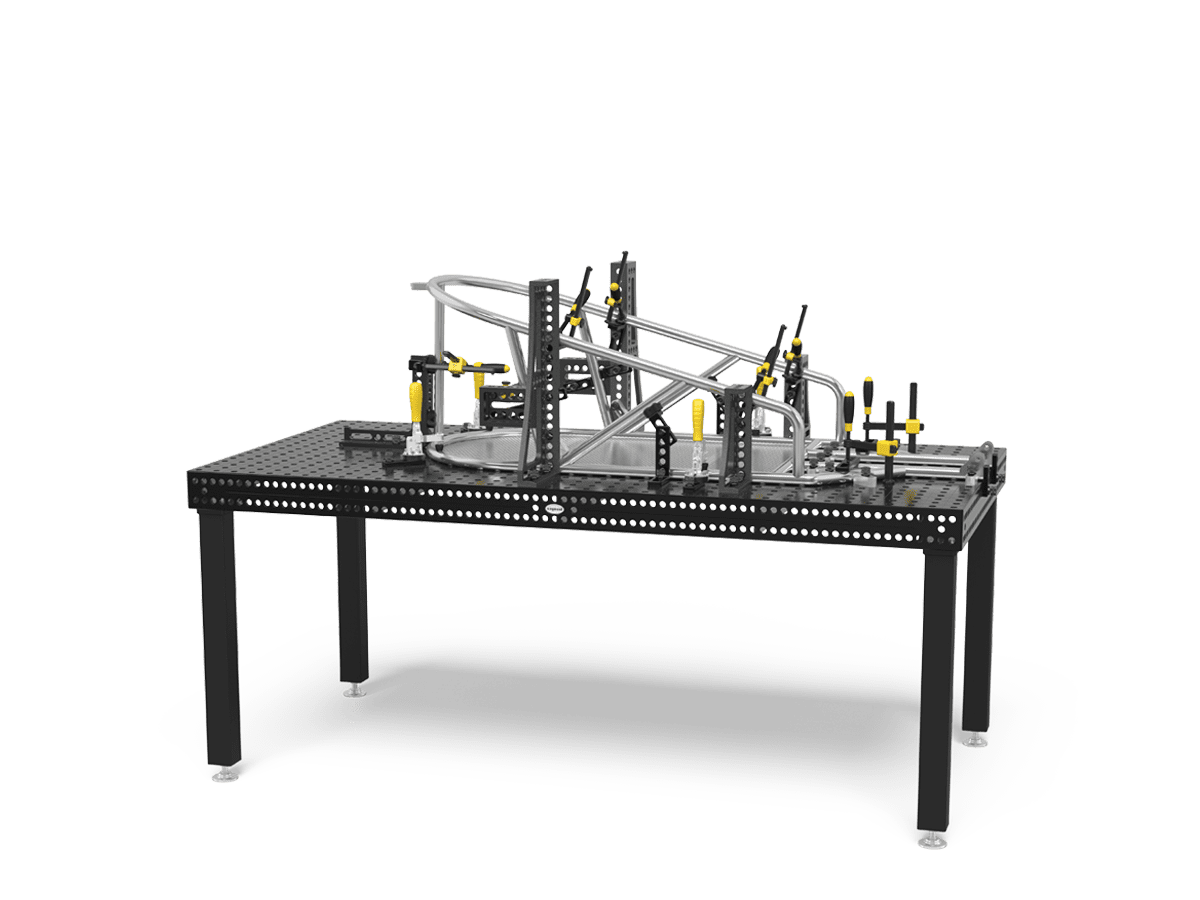

SYSTEM 22

Details

- Borehole Ø 22 mm

- Material thickness approx 17 – 19 mm

- Boreholes on the surface in diagonal grid or 100×100 mm grid

- Boreholes with radius 2,5 mm

- Height of table side 150 mm / 250 mm

- Recommended load up to 3000 kg*

max 1500 kg per leg basic equipment

We recommend our System 22 for fine details to medium heavy fabrications. For everyone who cannot decide.

SYSTEM 16

Details

- Borehole Ø 16 mm

- Material thickness approx 11,5 – 13 mm

- Boreholes on the surface 50×50 mm grid

- Boreholes with radius 2 mm

- Height of table side 100 mm / 150 mm

- Recommended load up to 2000 kg*

max 1000 kg per leg basic equipment

Our System 16 is the right decision for fine details fabrications, such as railings or frame constructions.

Materials

Through Hardened Tool Steel X8.7 + Plasma Nitration

-

Professional Extreme 8.7

-

Plasma nitrided

-

Basic hardness approx 280 – 340 vickers

-

Surface hardness approx 450 – 850 vickers

-

Well protected against rust, scratches and weld spatter

Through Hardened Tool Steel X8.7

-

Professional Extreme 8.7

-

Basic hardness approx 280 – 340 vickers

-

Unprotected against rust, scratches and welding spatters

-

Protection against welding spatters only when using anti spatter spray

Premium Steel S355J2+N + Plasma Nitration

-

Professional 750

-

Plasma nitrided

-

Basic hardness approx 165 – 220 vickers

-

Surface hardness approx 450 – 750 vickers

-

Well protected against rust, scratches and weld spatter

Premium Steel S355J2+N

-

Professional 750

-

Basic hardness approx 165 – 220 vickers

-

Unprotected against rust, scratches and welding spatters

-

Protection against welding spatters only when using anti spatter spray

Premium Stainless Steel X5CrNi18-10 (1.4301)

-

Basic hardness approx 266 – 382 vickers

-

Ideal for work on stainless steel components

-

Especially suited for environments with high corrosion requirements (e.g. pharmaceutical and food industry)