SIEGMUND

Materials Comparison

Material Options & Surface Protection

Engineered for performance, built for longevity

Siegmund tables are available in a range of high quality materials, including standard steel, high grade tool steel and corrosion resistant stainless steel. Each material option can be enhanced with plasma nitriding, allowing users to match their table selection to specific performance and durability requirements.

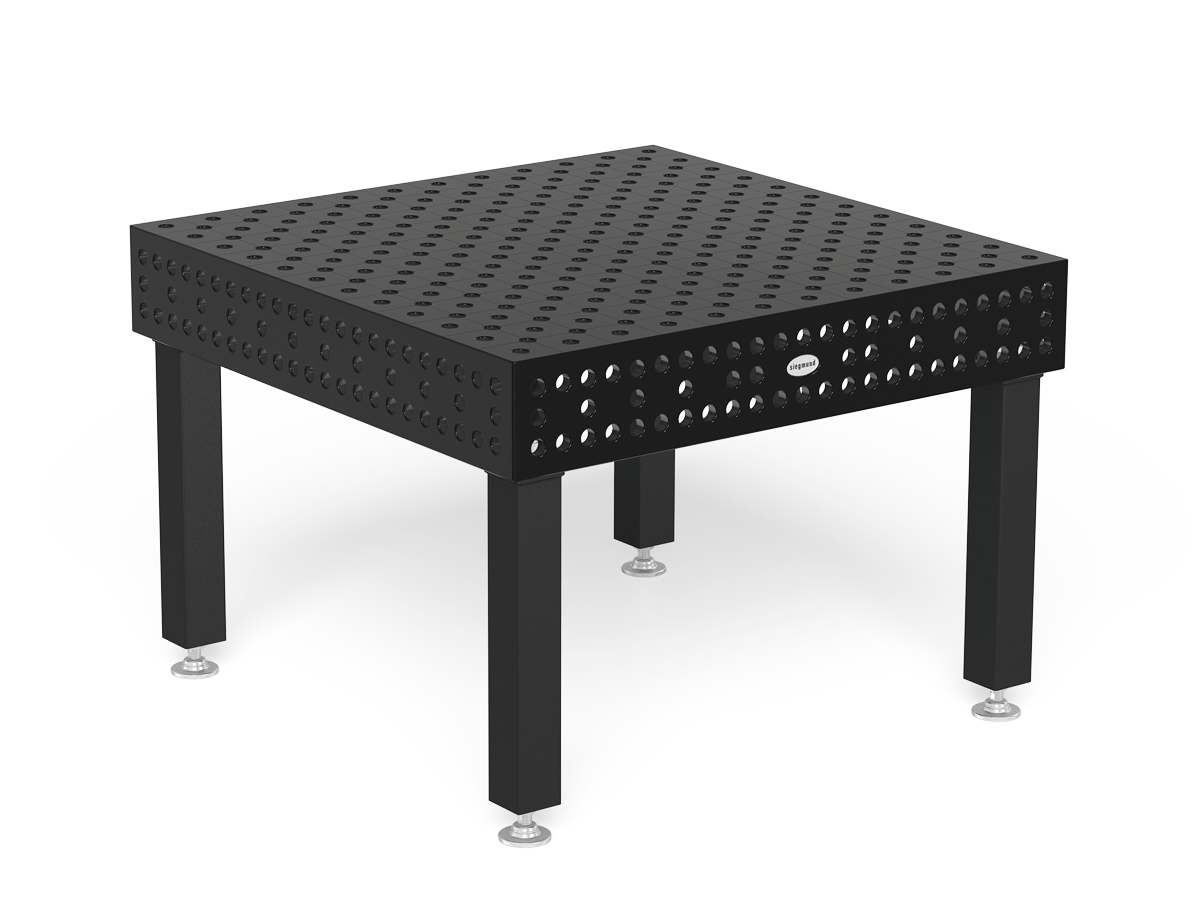

The exclusive X8.7 and X8.8 tool steels offer significantly higher base hardness compared to conventional options, ensuring superior impact resistance and a longer service life. Combined with advanced plasma nitriding and BAR coating, these surfaces gain enhanced protection against wear, corrosion and weld spatter, ideal for demanding industrial environments.

Through-hardened tool steel X8.8

-

Professional Extreme 8.8

-

Base hardness: 360–420 Vickers

-

Surface hardness: 500–900 Vickers

-

Highly wear resistant

-

Extremely hard core material

Through-hardened tool steel X8.7

-

Professional Extreme 8.7

-

Base hardness: 280–340 Vickers

-

Surface hardness: 450–850 Vickers

-

Significantly more durable than conventional steel

Premium steel S355J2+N

- Professional 750

- Basic hardness: approx 165 – 220 Vickers

- Surface hardness after plasma nitriding: approx 450 – 750 Vickers

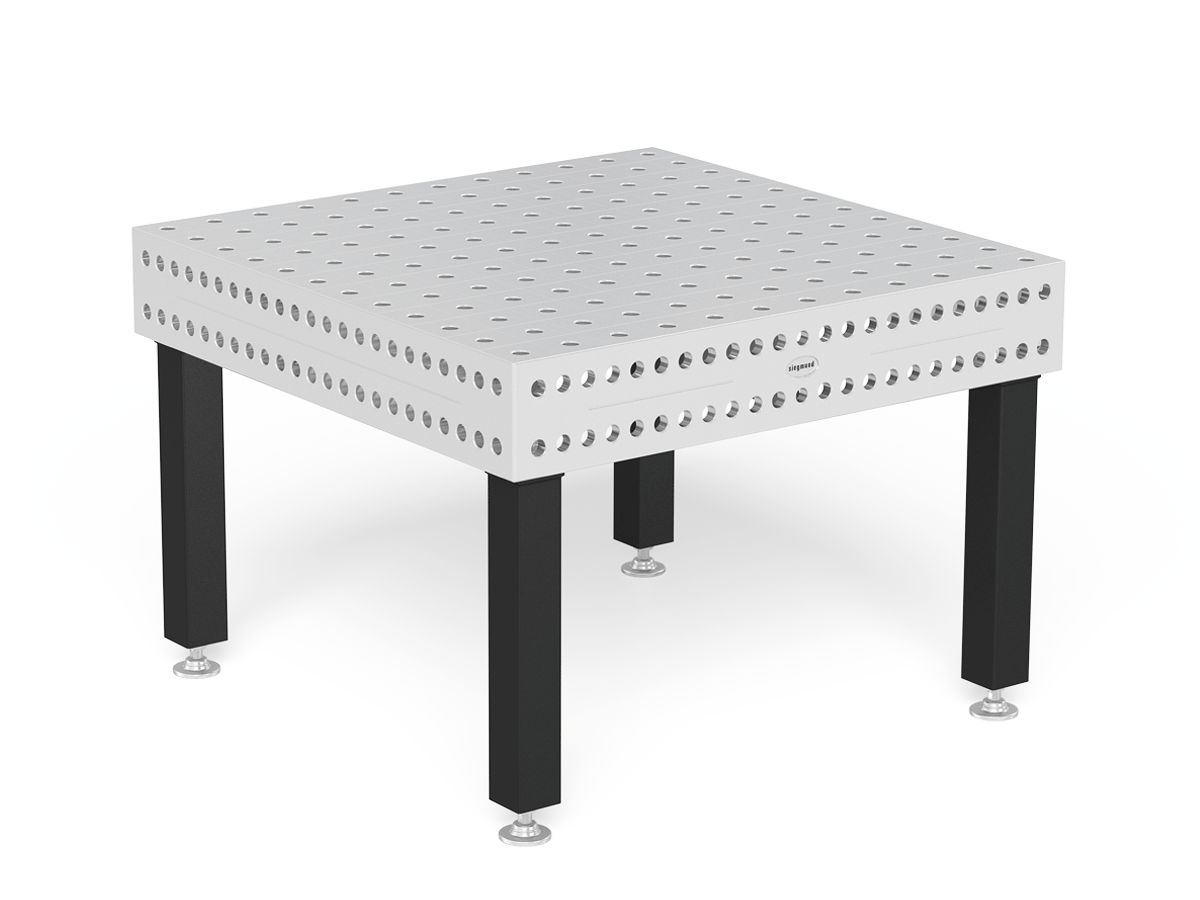

Premium stainless steel X5CrNi18-10 (V2A)

-

Basic hardness: approx 266 – 382 Vickers

-

For stainless steel processing

- Corrosion resistant

Materials Comparison

Plasma Nitration

Proven surface treatment for long lasting welding tables

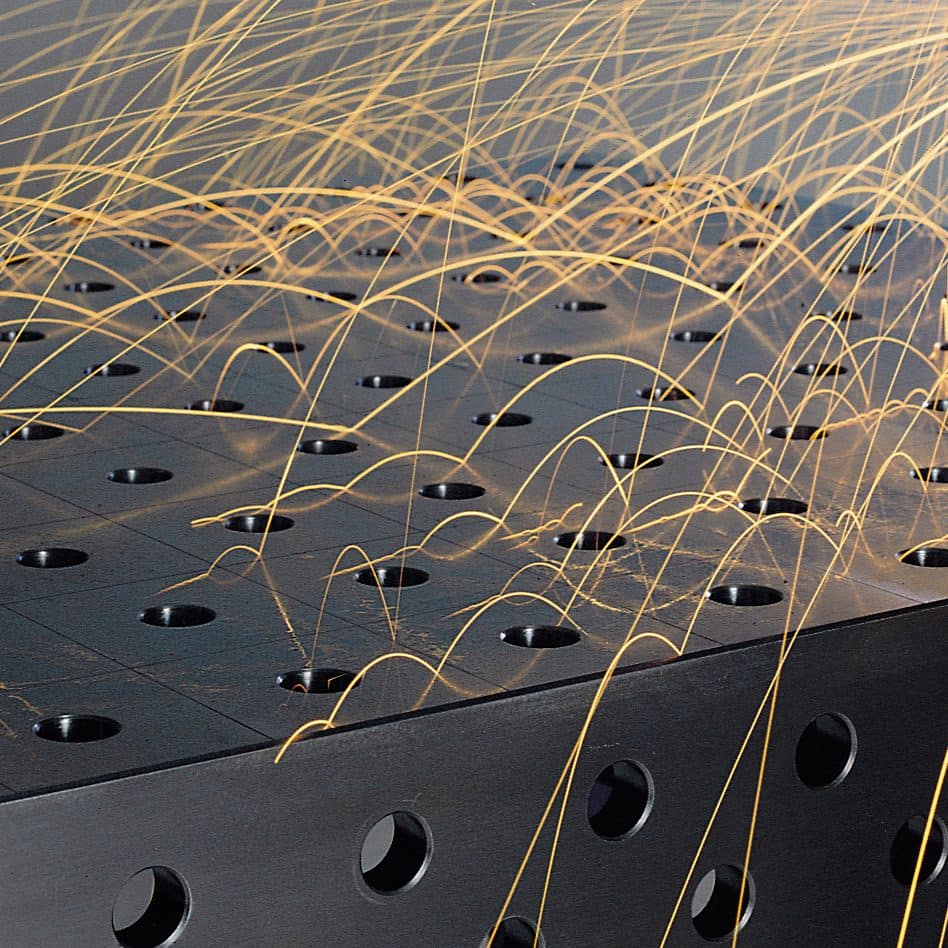

Siegmund’s welding tables have been plasma nitrided as standard since 2009. With years of experience and ongoing process optimisation, Siegmund have developed a welding table that stands out for its robustness and durability, making it nearly unmatched by other products.

What is plasma nitration?

Plasma nitriding is a vacuum based heat treatment that hardens the surface by diffusing nitrogen into the material at around 500 °C, creating a wear and corrosion resistant layer. The process produces minimal distortion and is environmentally friendly, using only nitrogen, hydrogen and oxygen gases naturally found in air. At Siegmund, the process is powered entirely by electricity, avoiding fossil fuels commonly used elsewhere.

Higher Wear Resistance

Corrosion Protection

Minimised Warping

Reduced Weld Spatter Adhesion

Durable Protection No Re-Treatment

BAR Coating

Unique to Siegmund is the BAR coating applied after plasma nitriding to welding tables and many tool parts. This Black Anti Rust (BAR) Coating further smooths the surface and enhances protection against corrosion.

-

Reinforced rust protection

-

Additional grading and surface refinement

System Comparison

Compare the different Siegmund welding table systems, focusing on key features, performance and how each system fits specific welding and fabrication needs.

Table Series

Browse through our comprehensive range of table series, tailored to meet the specific demands of your welding and fabrication needs.