SIEGMUND

Table Series

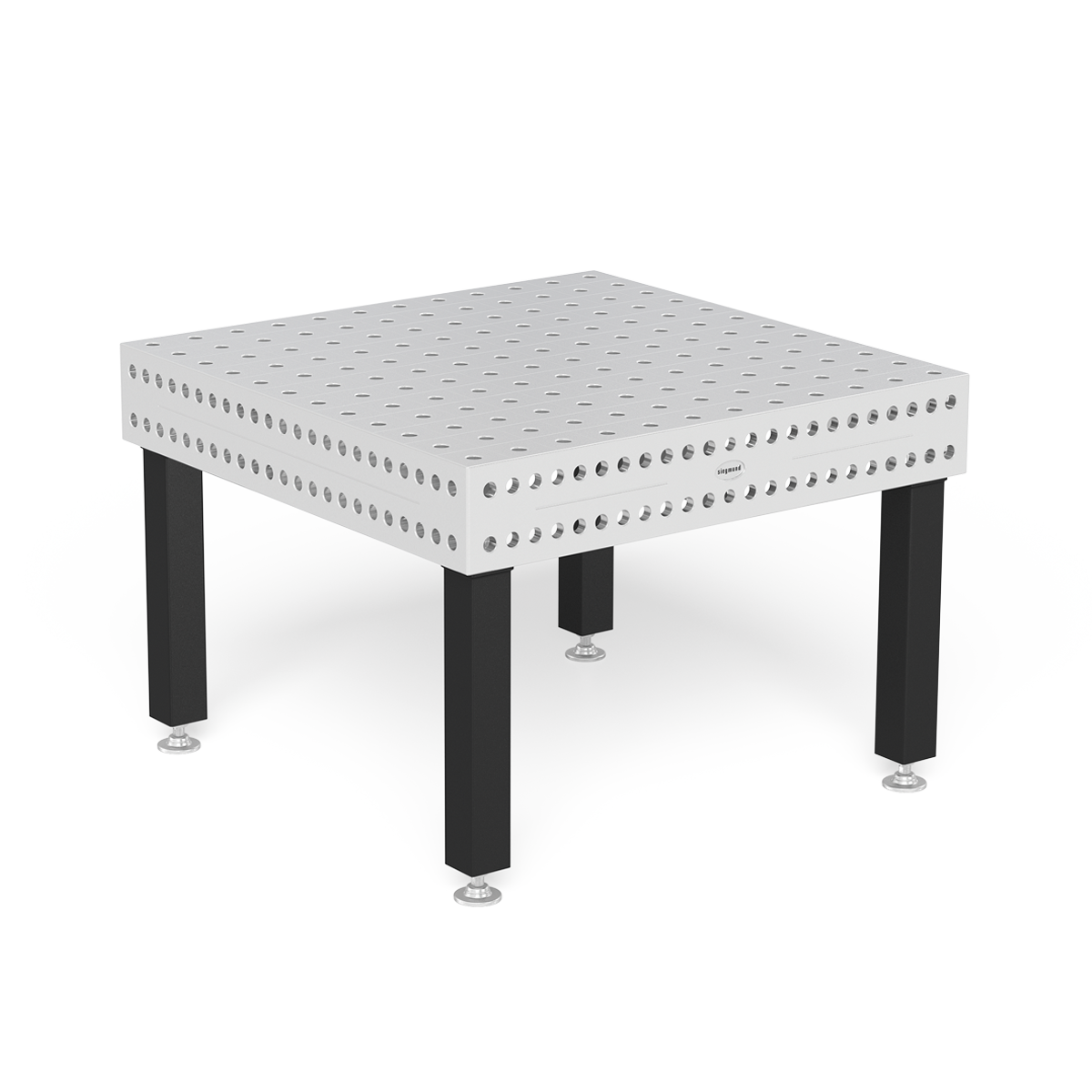

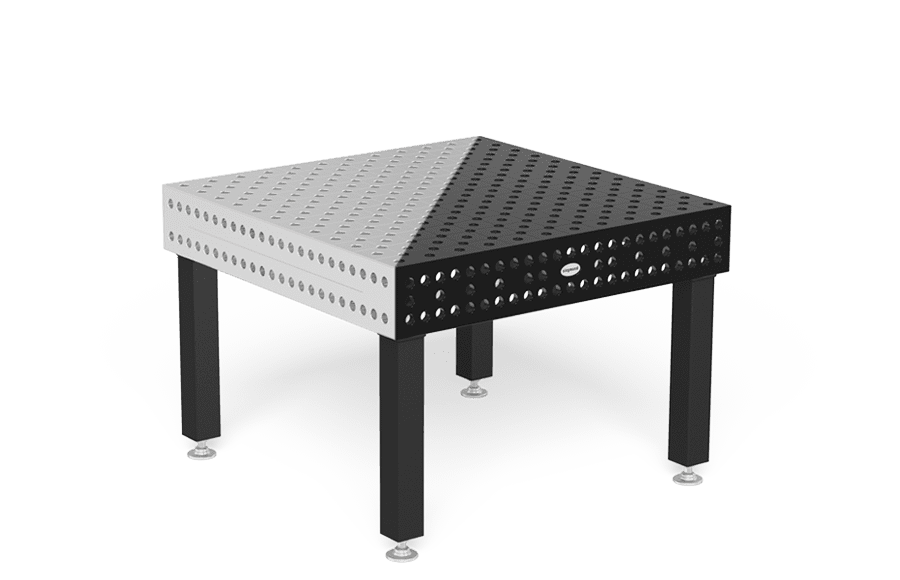

Choose the table series that fits your needs. Siegmund offers a range of welding tables crafted from premium materials, each designed for durability, precision and flexibility. Every table series is available in multiple sizes and can be configured with a variety of leg options to suit your workspace. Whether for light assembly or heavy fabrication, there’s a table built for the task.

Decide On Your Table

Basic 750

Premium steel S355J2+N

Plasma nitrided and BAR coated (System 16)

Suitable for basic applications

No or reduced height side panel

Basic 8.7

Through hardened tool steel X8.7

Plasma nitrided and BAR coated

Suitable for basic applications

Without side panel

Professional 750

Premium steel S355J2+N

Plasma nitrided and BAR coated

Suitable for more complex work

Side panel with two rows of boreholes

Professional Extreme 8.7

Through hardened tool steel X8.7

Plasma nitrided and BAR coated

Significantly higher base hardness

Maintains high precision over time

Ideal for demanding work

Side panel made of steel S355J2+N

Professional Extreme 8.7 PLUS

Through hardened tool steel X8.7

Plasma nitrided and BAR coated

Significantly higher base hardness

Maintains precision even after extended use

For particularly demanding work

Side panel made of steel S355J2+N

Enhanced rigidity from extra high side panels and internal ribbing

Professional Extreme 8.8 PLUS

Stainless Steel

Premium stainless steel X5CrNi18-10 (V2A)

Recommended for applications with stainless steel

Corrosion resistant

T-Slot Tables

Premium steel S355J2+N

Plasma nitrided and BAR coated

Flexible clamping with multiple options

Cross slots, lengthways slots, transverse slots

Additional threaded boreholes for enhanced clamping possibilities

Hexagon Slot Table

Through hardened tool steel X8.7

Plasma nitrided and BAR coated

Flexible clamping with multiple options

Features transverse hexagonal slots

Same load capacity as standard welding tables

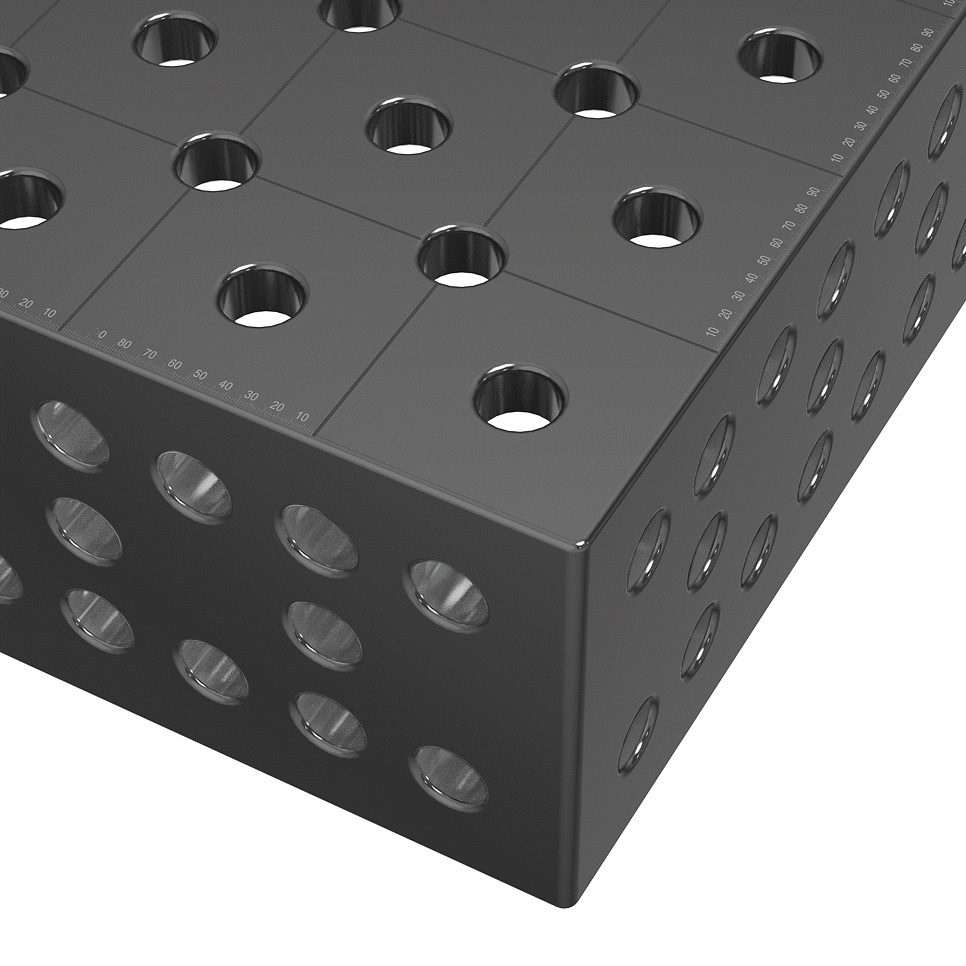

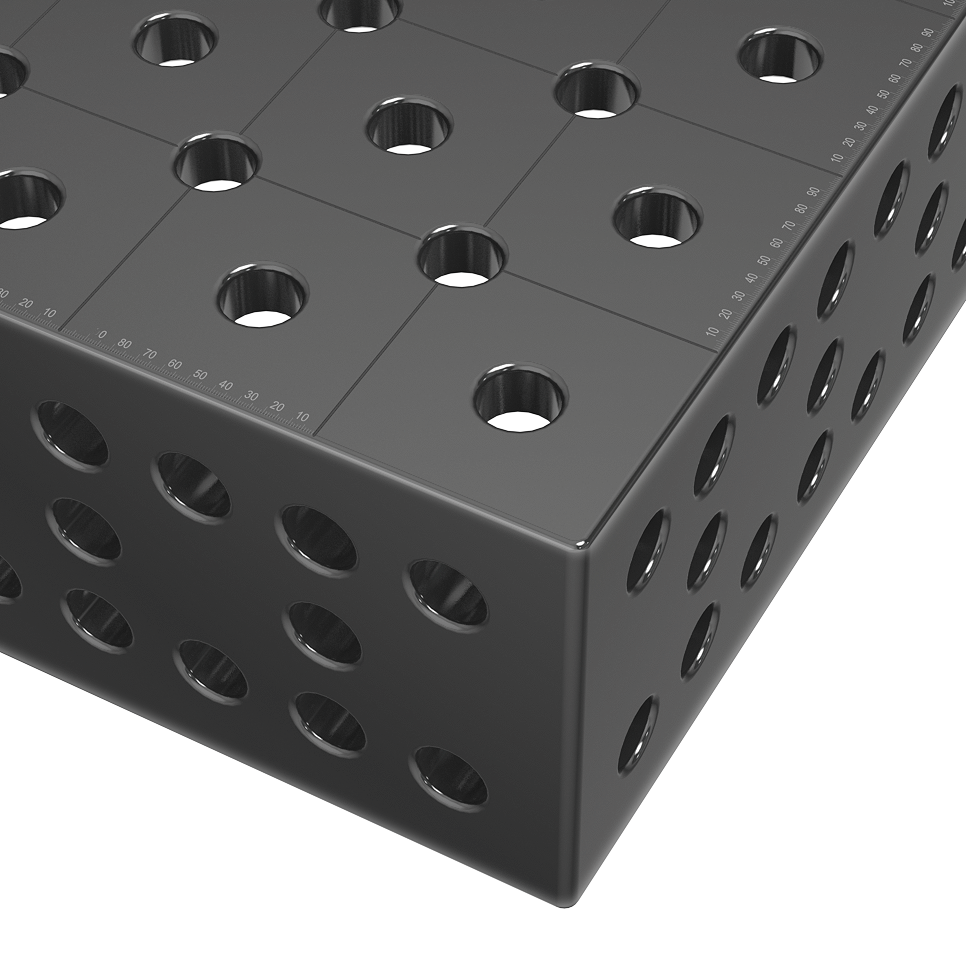

Boring Grid

100 mm Grid / 50 mm Grid

The 100 mm grid of Systems 28 and 22 as well as the 50 mm grid of System 16 form the precise foundation for the entire Siegmund modular system.

Diagonal Grid

The diagonal grid offers twice as many clamping options in the diagonal. Take advantage of the increased flexibility to clamp even more versatile setups.

Diagonal Grid for Table Sides

The diagonal grid on the side panel provides additional options for attaching tool parts.

Special Equipment

50 mm Grid (System 28 & 22)

For System 28 and 22 welding tables, the standard borehole spacing on the surface is 100 mm. For more clamping options, the tables are also available with a 50 mm borehole spacing upon request.

Table Sides Double Hardened

The side panels of all Siegmund welding tables (except stainless steel tables) are made of high quality S355J2+N steel. For particularly demanding applications, you can also get your table with a side panel made of through hardened tool steel.

Threaded Surface Holes

Special diagonal grid with additional threaded holes for attatching tools and fixtures. Available with M8, M12 or M16 threads.

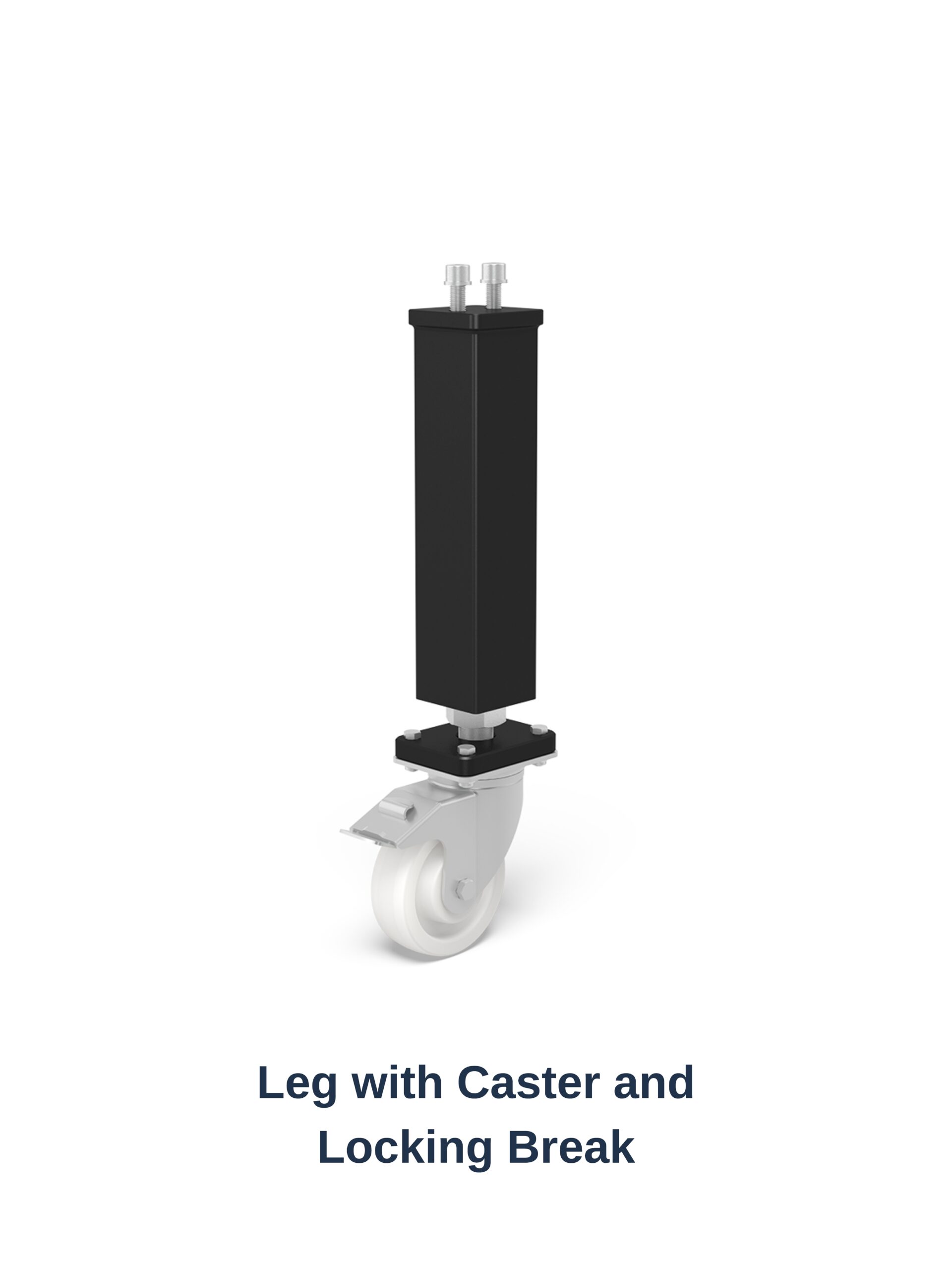

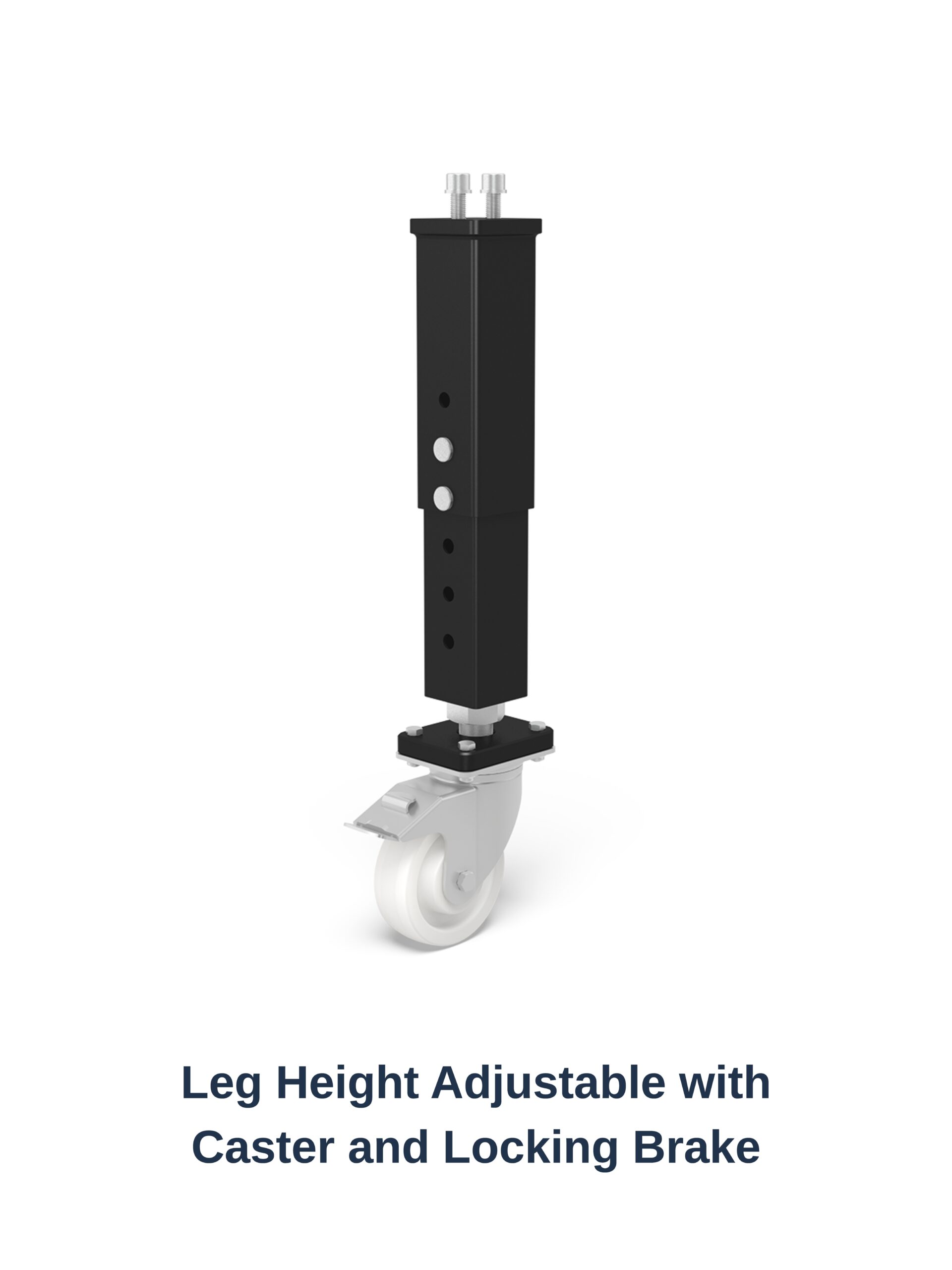

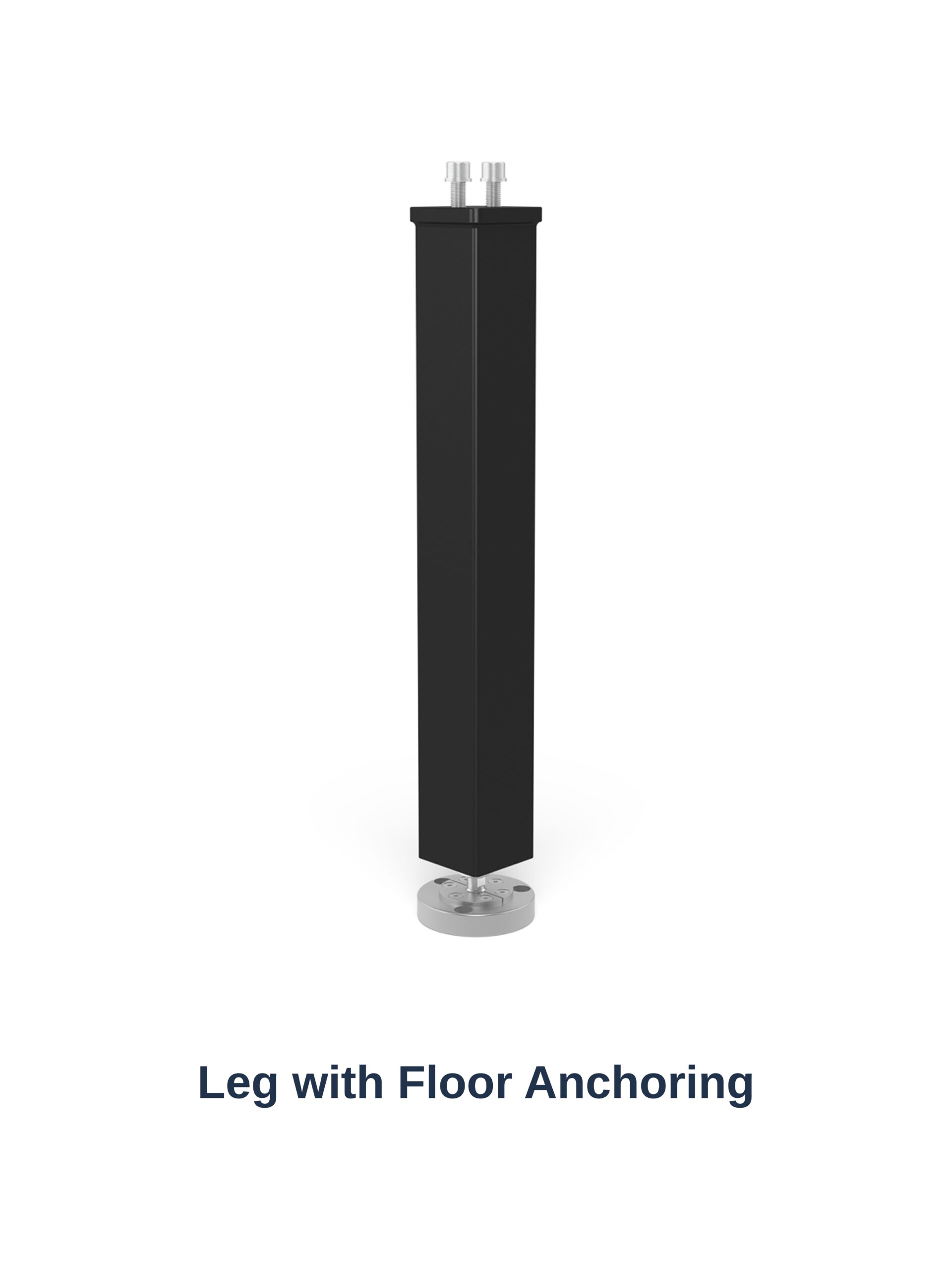

Table Legs

Siegmund welding tables come equipped with standard legs by default. To meet your individual requirements and offer maximum flexibility, you can also choose from a range of alternative table legs.

System Comparison

Compare the different Siegmund welding table systems, focusing on key features, performance and how each system fits specific welding and fabrication needs.

Materials Comparison

Dive into the various material options available, understanding their strengths, durability and best use cases for your projects.