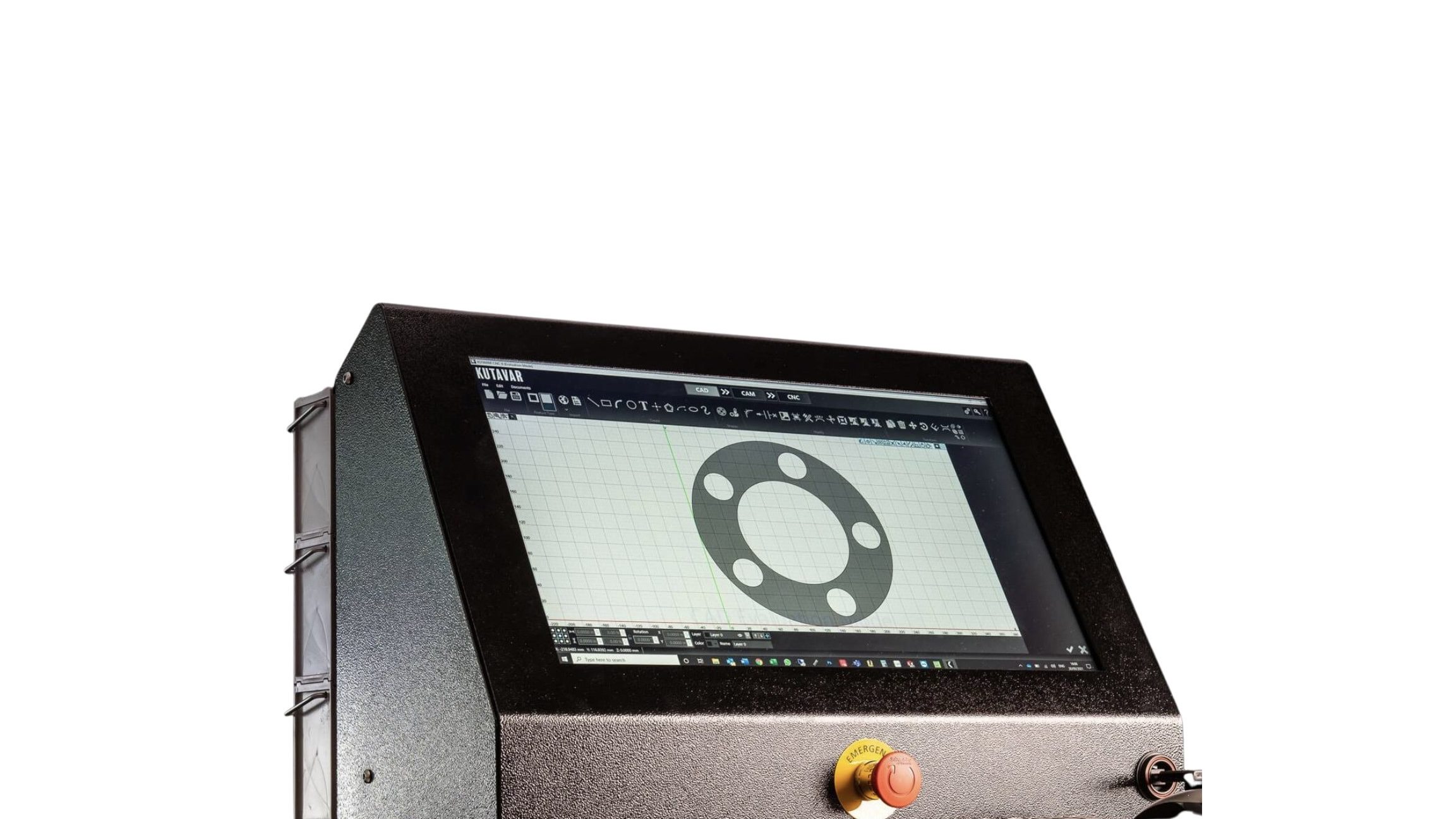

KUTAVAR

Software

Kutavar Software delivers a fully integrated CAD, CAM and CUT solution built to simplify and streamline CNC plasma cutting. Whether you’re designing parts from scratch or importing existing DXF files, its intuitive interface and smart tools make it easy to draw, nest and cut with confidence. With built in cutting parameters, automated cost calculations and seamless support for both plasma and oxyfuel systems, Kutavar ensures efficient, accurate results from start to finish.

Easy Design

Design shapes, import files or trace images, no CAD experience needed.

Smart Workflow

Modify, nest and cut in one flow, true shape nesting minimises waste.

Precise Cutting

Charts set cutting parameters for plasma and oxy-fuel, no guesswork.

Cost Calculation

Enter material cost per KG to get instant, accurate part pricing during nesting.

Software Overview

CAD Features

✔ Built in shape library and shape welding tool

✔ Fix drawing, bridge entities and measuring tools

✔ Free form stretching and manipulation

✔ Layer, centreline and silhouette image support

✔ Multi layer colour image import

✔ DXF/DWG import with arc fitting

CAM Features

✔ Trueshape and grid nesting

✔ Automatic kerf compensation

✔ Tabbing, corner looping and overburn support

✔ Advanced lead in/out editing

✔ 3D animated cutting simulation

✔ Drag, rotate, copy and delete parts on nest

✔ Multi sheet and fill sheet nesting

CNC Features

✔ Automatic lead in on restart

✔ Jump to line, dry run and file playback controls

✔ Dynamic THC on/off with performance history

✔ Smart touch off and kerf crossing detection

✔ Progress meter and viewport point navigation

✔ Rip cutting support

Applications

✔ Supports plasma, oxy-fuel and marking tools

✔ DXF export and part shading

✔ Customisable cut charts and material database

✔ Common plate list and printing support

✔ TrueType fonts with curved text around shapes

✔ 3D simulation and label printing options

Software Videos

Nesting Overview

Import Silhouette Overview

Shape Overview

FAQ’s

How much does the software cost?

Kutavar includes the software within the offer for the machine. It is a complete package with no ongoing fees.

How many licences do I get?

As standard, your new Kutavar will come complete with two licences. One is on the machine itself and the other on a computer of your choice.

Can I edit existing files?

Kutavar software is a complete CAD – CAM – CNC suite. This allows you to not only edit existing files but also design and create custom parts.

What files can I import?

Kutavar supports the import of DXF, DWG and CADCAM files. Through our software, you can also create a cutting outline of PNG and JPEG image files.

Can I simulate the cutting of parts?

Through a combination of our ‘dry run’ feature, advanced 3D simulation and visible G-code, you can easily simulate your toolpath before a cut has been made. This allows you to produce parts right the first time.

Can it be used for multi torch setups?

Available with all Kutavar zoned extraction tables is the option of cutting with Oxy-fuel. A simple manual changeover allows the operator to alternate between plasma and gas cutting quickly.

Can it be used remotely?

With TeamViewer, the Kutavar software can be accessed remotely for support or training. The software can also be installed on additional computers, allowing you to transfer and access files across your I.T. network.

Does the software include templates?

Kutavar software includes an extensive library of basic pre loaded shapes, from baseplates to flanges to brackets. All parts are completely customisable.

Can it compensate for warping?

Kutavar includes accurate Torch Height Control (THC) software, in combination with voltage sampling, constantly measuring the distance between the torch and the workpiece during a cut.

An inconsistent distance between the torch and the workpiece will negatively impact the quality of the cut (e.g. increased dross build up, bevelling and rough edges).