SIEGMUND

Zero Point Clamping System

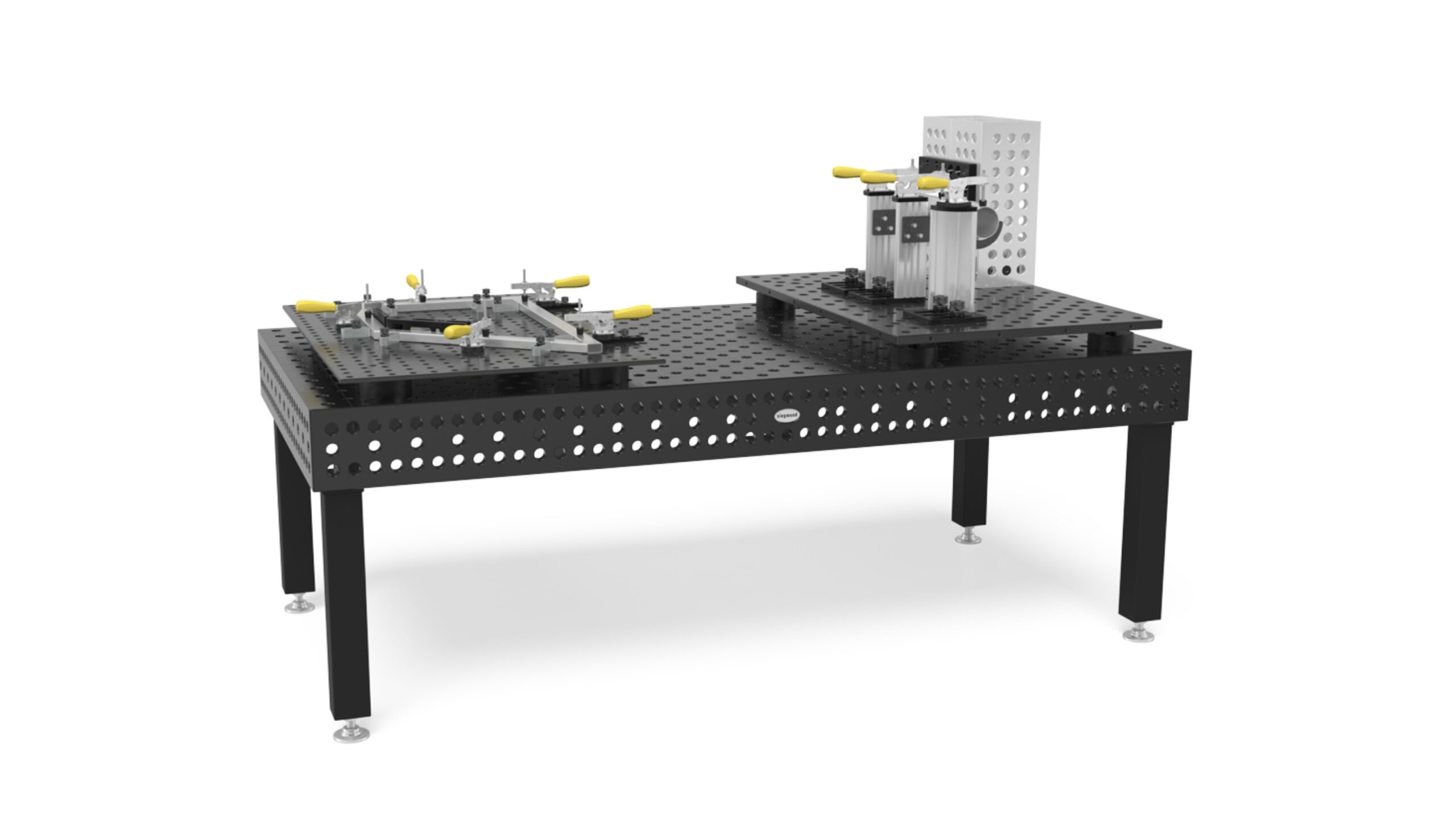

Easily swap welding fixtures with the Siegmund Zero Point Clamping System, available at MPAC. Designed for quick, flexible changes, it’s ideal for both manual and robotic workstations. With high repeat accuracy, precise zeroing and mechanical or pneumatic actuation, it boosts efficiency and ensures consistent quality. The system offers fast setup, simple operation and smooth integration into existing workflows.

Flexibility

Quick fixture swap

Pneumatic option

Fits all tables

PRECISION

High accuracy

Easy zeroing

Fast set up

USABILITY

Simple operation

Tool free change

Robotic ready

DURABILITY

Long lasting

Strong clamping

Reliable system

Advantages

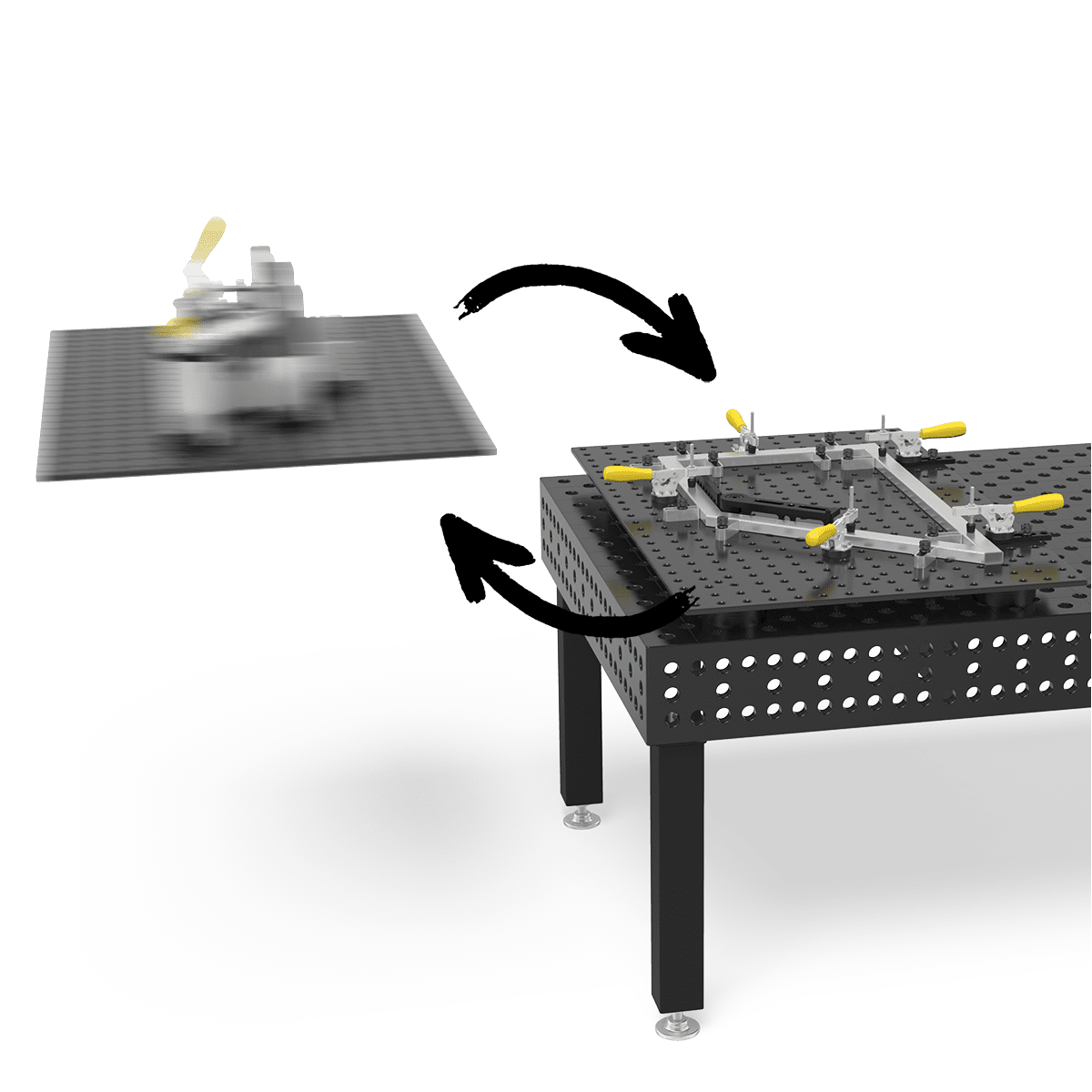

Quick Fixture Change

Simply remove and replace the complete perforated plate and fixture assembly and replace with another.

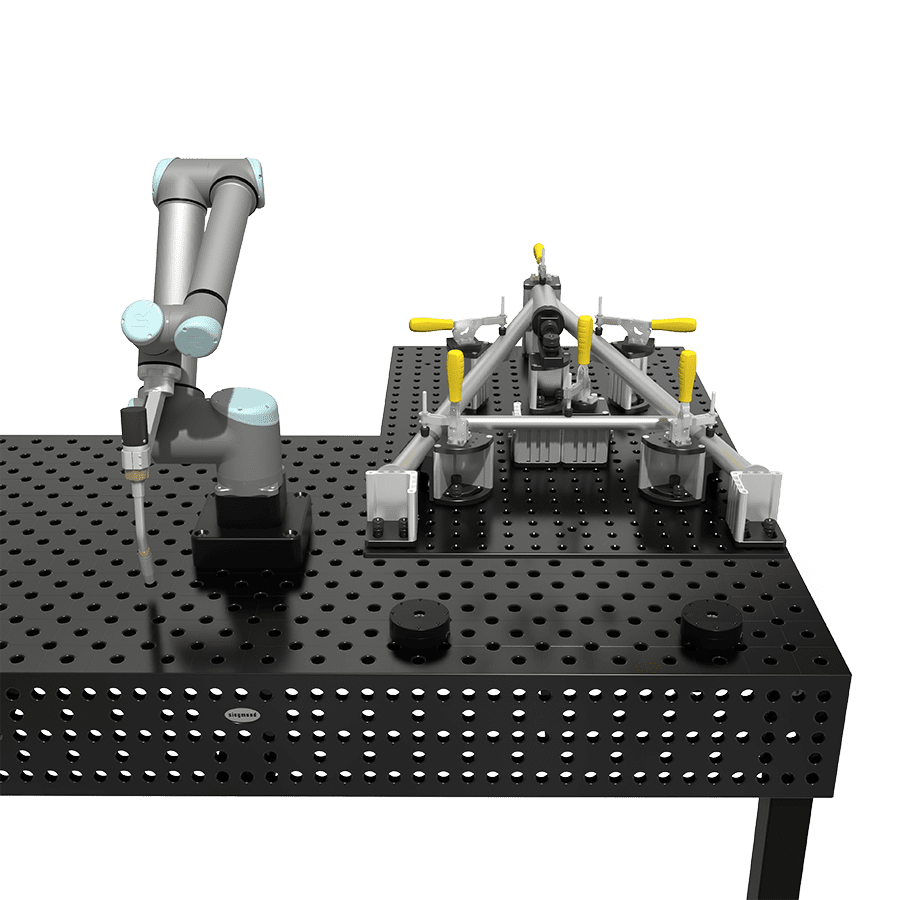

Produce In Series

Automate your workplace now with Siegmund’s zero point clamping system and upgrade your welding table to increase the robot working load and ensure consistent quality.

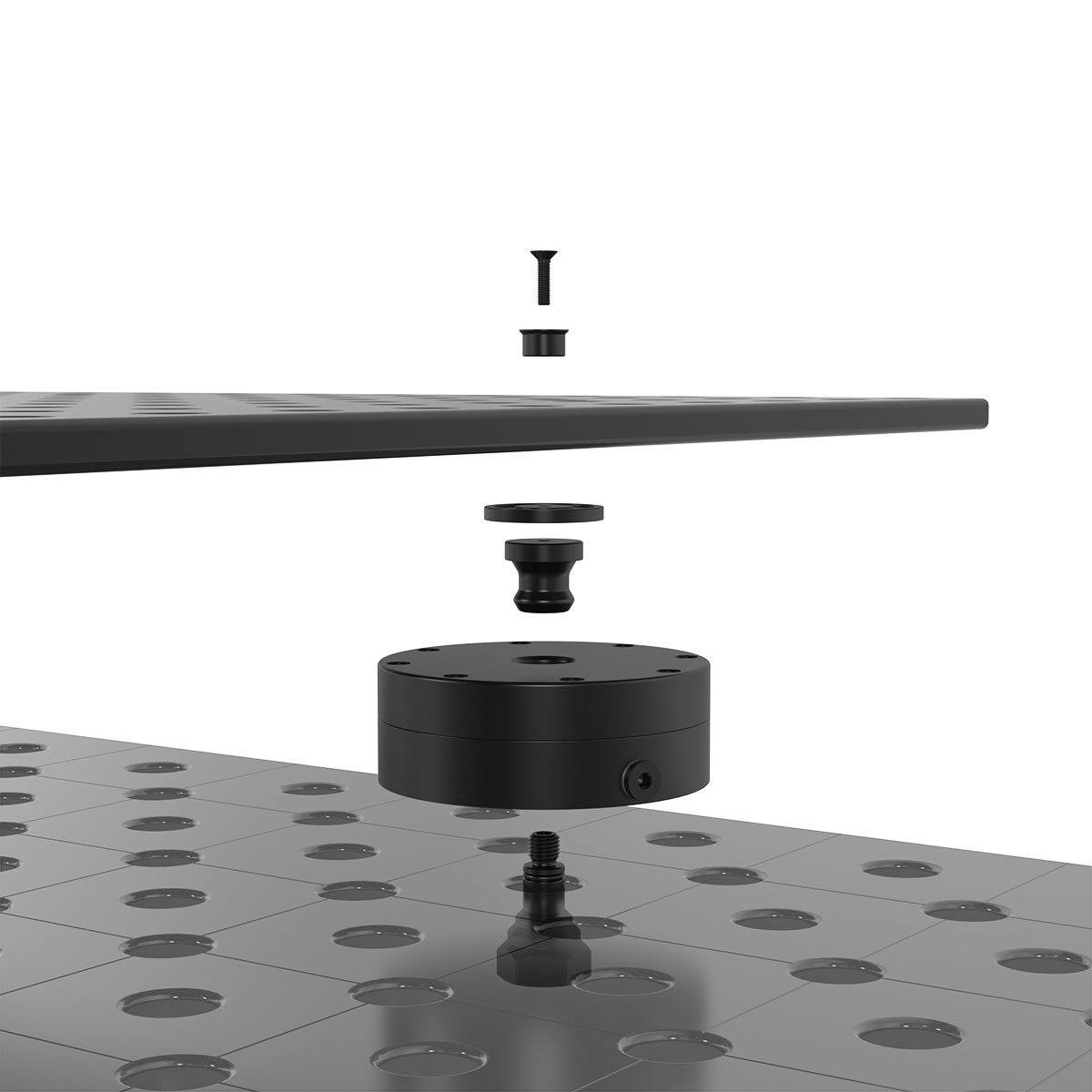

Simple Usage

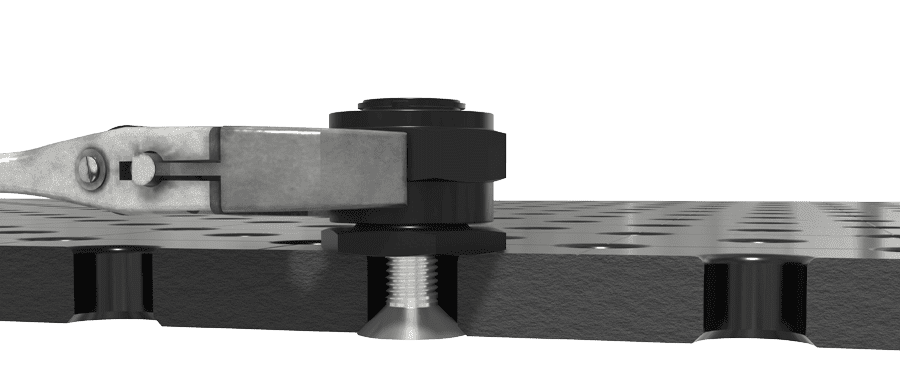

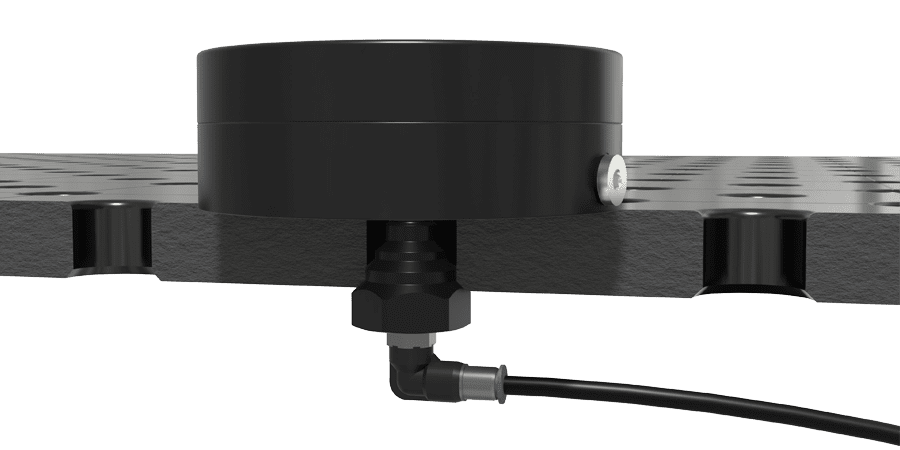

The zero point clamping modules are centered and secured in the welding table boreholes, fastening the perforated plate with clamping bolts.

Precise Zeroing

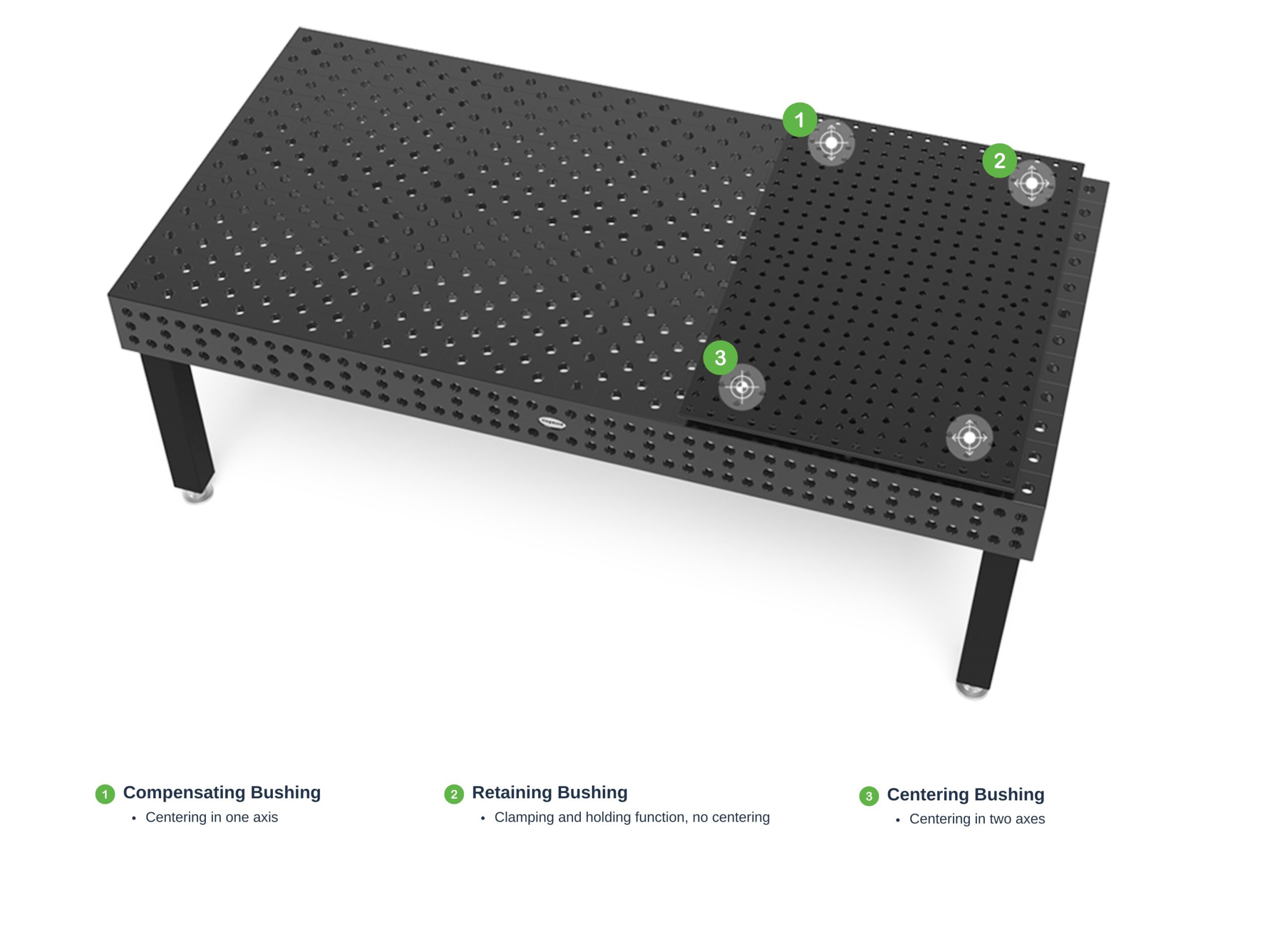

The perforated plate can be aligned on the welding table with the zero point clamping system. The centering is done via the sockets.

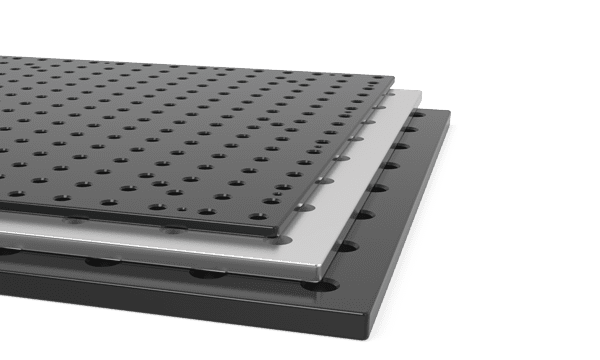

Versions

Mechanic

The mechanical version clamps and releases manually using an open jaw wrench.

Pneumatic

The pneumatic version clamps automatically and releases with compressed air.

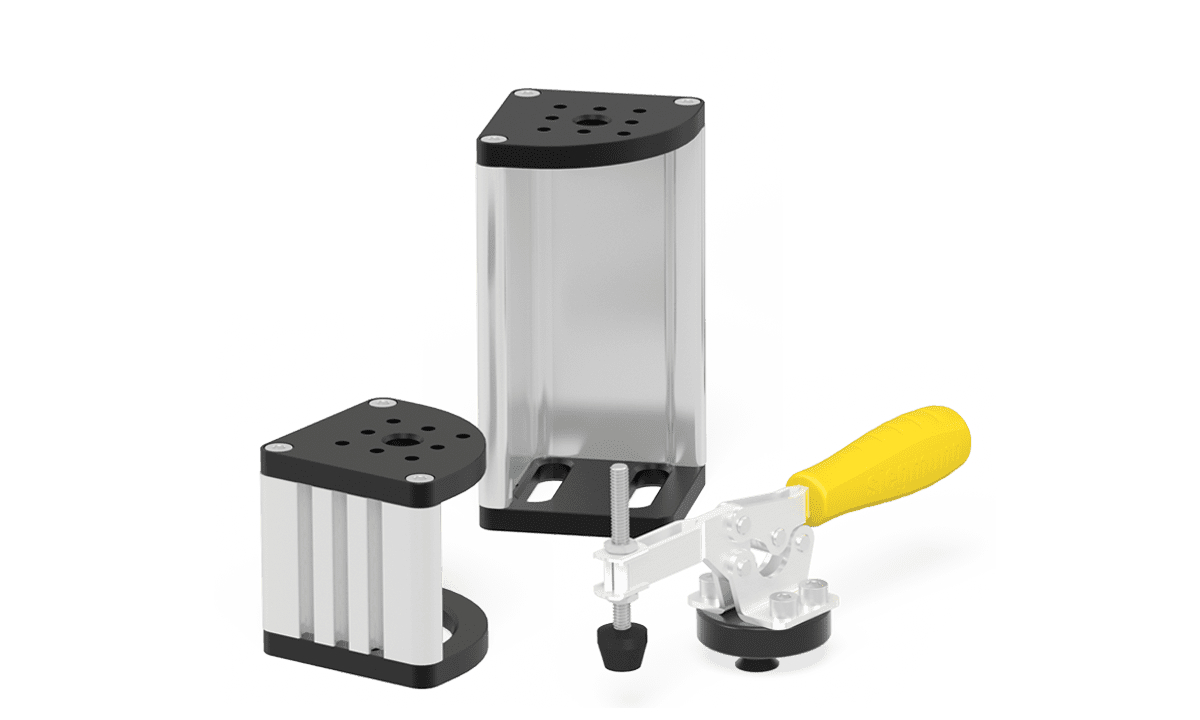

Suitable Products

Clamping System

In combination with the new clamping system, recurring welding devices can be manufactured with high accuracy and low down times. If a robot program already exists, you benefit from a minimal set up time of your device.

Preforated Plates

Plasma nitrided perforated plates are available with various system boreholes, 16 mm, 22 mm and 28 mm in diameter and in a range of materials. The surface boreholes allow for easy fastening of components using Siegmund tooling.