SIEGMUND

Clamping system

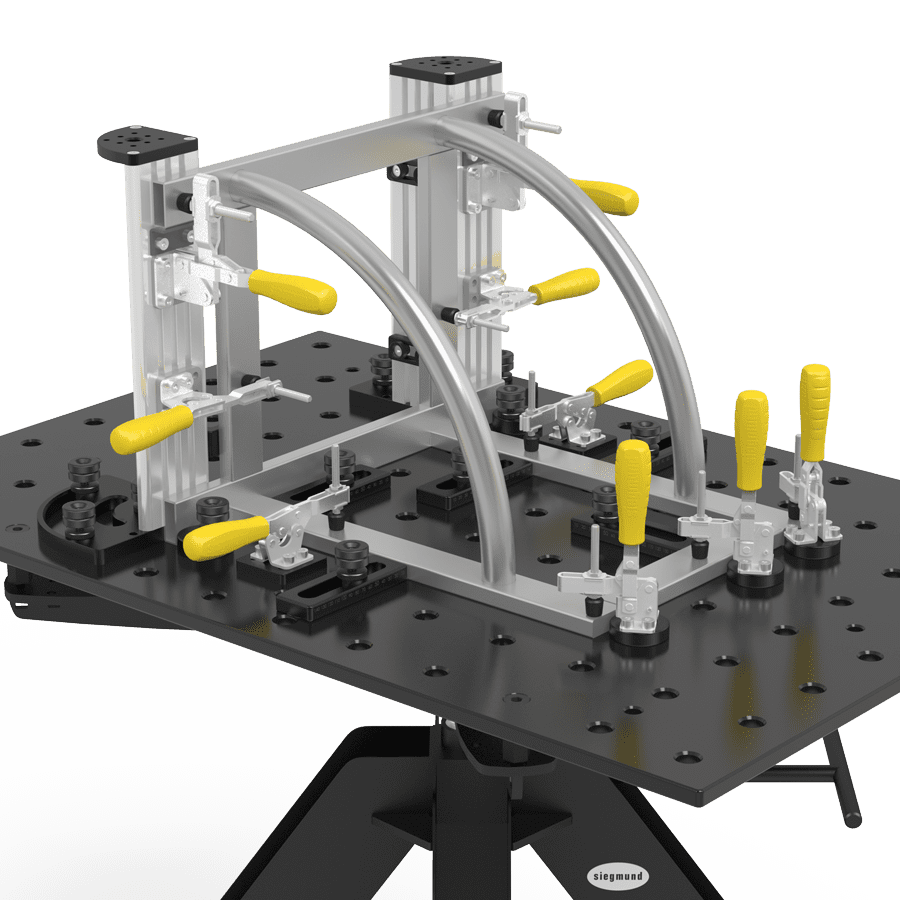

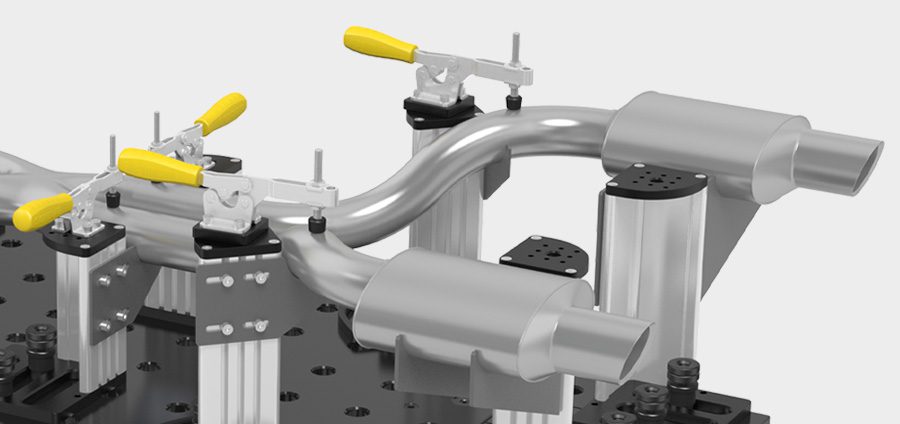

Easily create custom fixtures with the Siegmund Clamping System, available at MPAC. Use adjustable aluminium profiles, base and cover plates for quick, cost effective production. Compatible with laser or 3D printed templates, it’s ideal for welding, assembly and more, offering precision, flexibility and full integration with the Siegmund product range.

Precision

Custom fixtures

Modular design

Height adjustable

SIMPLICITY

Quick assembly

T-Slot connect

Easy adjustments

Performance

Fits Siegmund

Works with templates

Full accessory range

DURABILITY

High quality

Reliable fixations

Long-lasting

Advantages

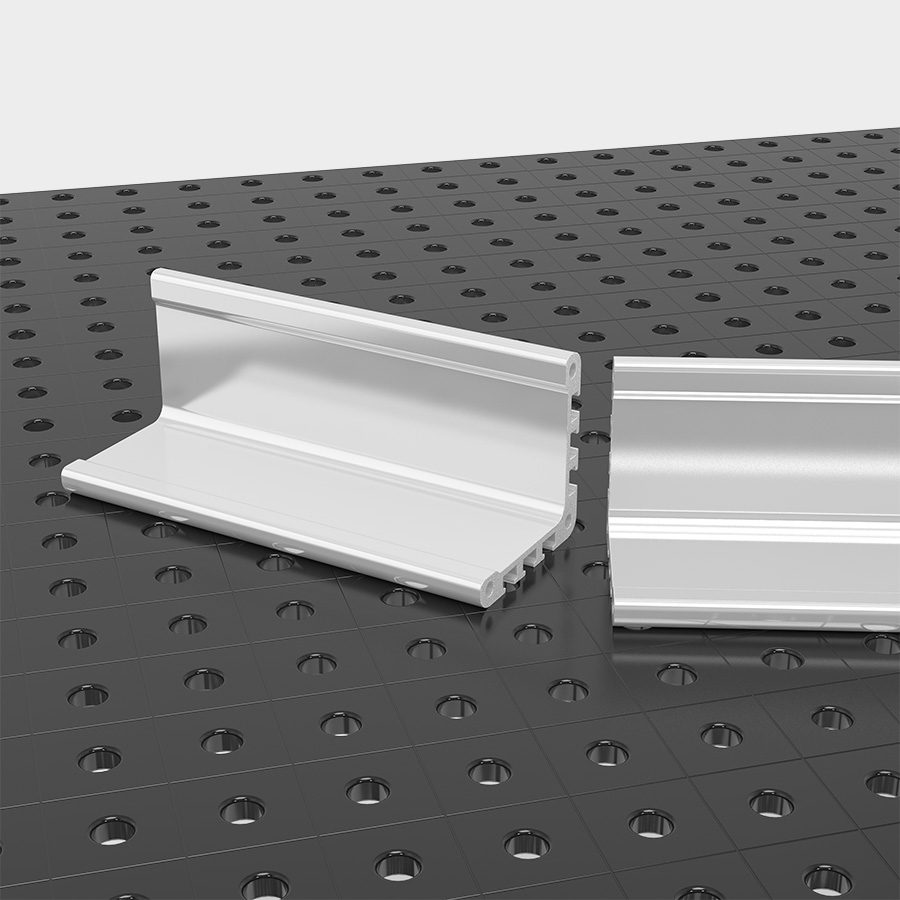

Working with Templates

Whether parts are from a laser or 3D printer, parts can be attached to the profile in the T-Slot with square nuts and screws.

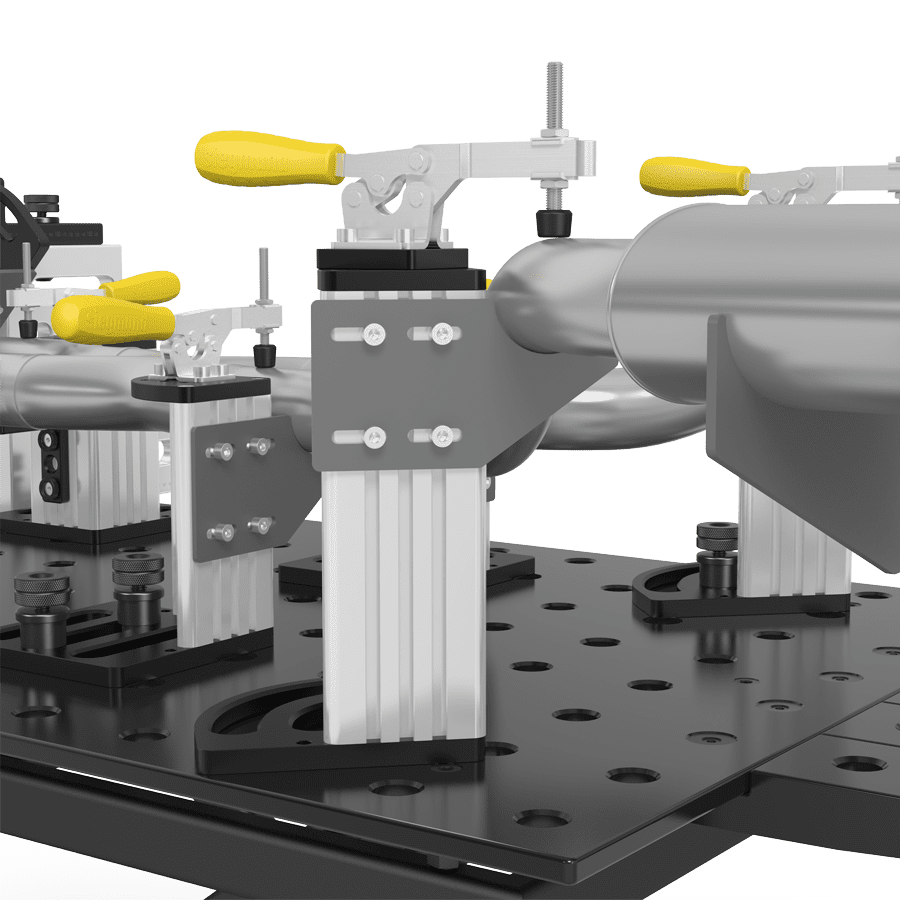

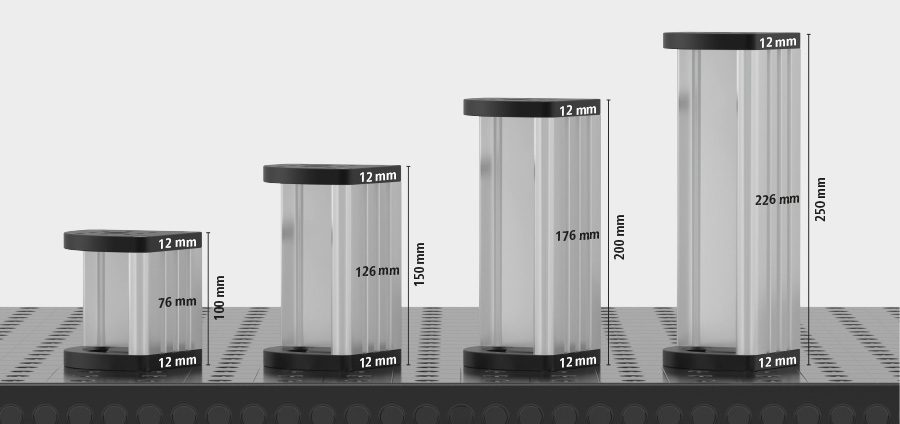

Individual Height

✔ Components heights set by aluminum profile length

✔ Individual height adjustment from cut lengths

✔ Profiles available in fixed lengths and as mass product

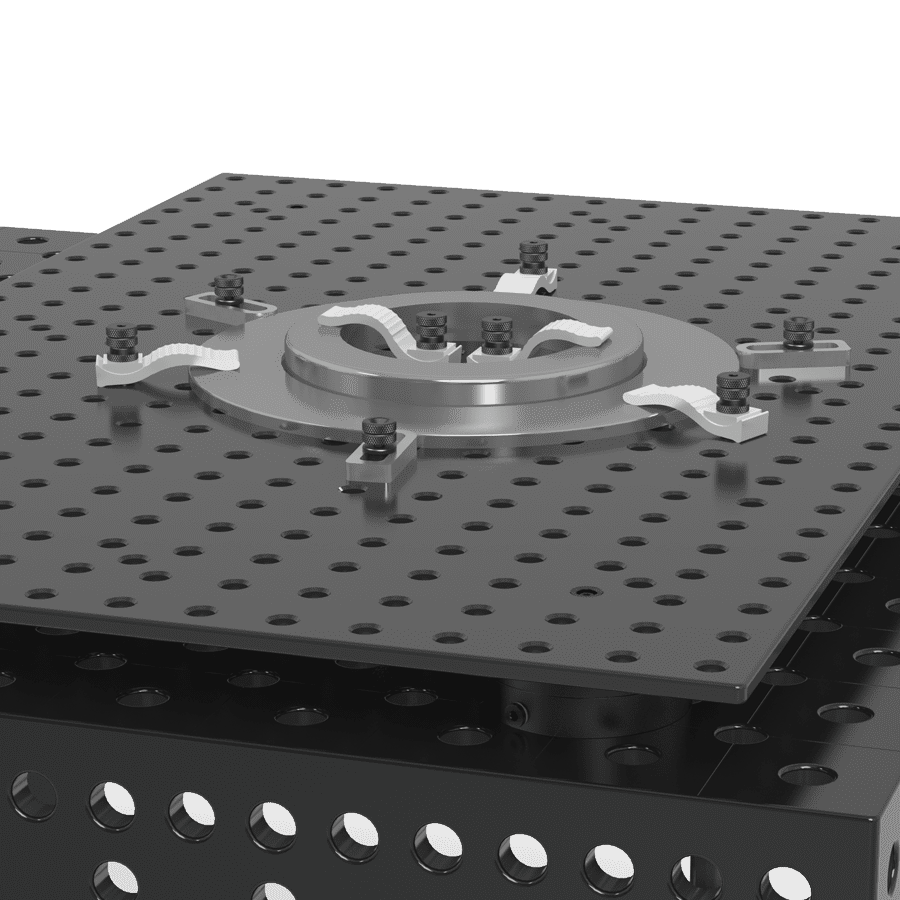

Compatibility

The fixture system is compatible with all the Siegmund product range.

Create Your Individual Fixture System

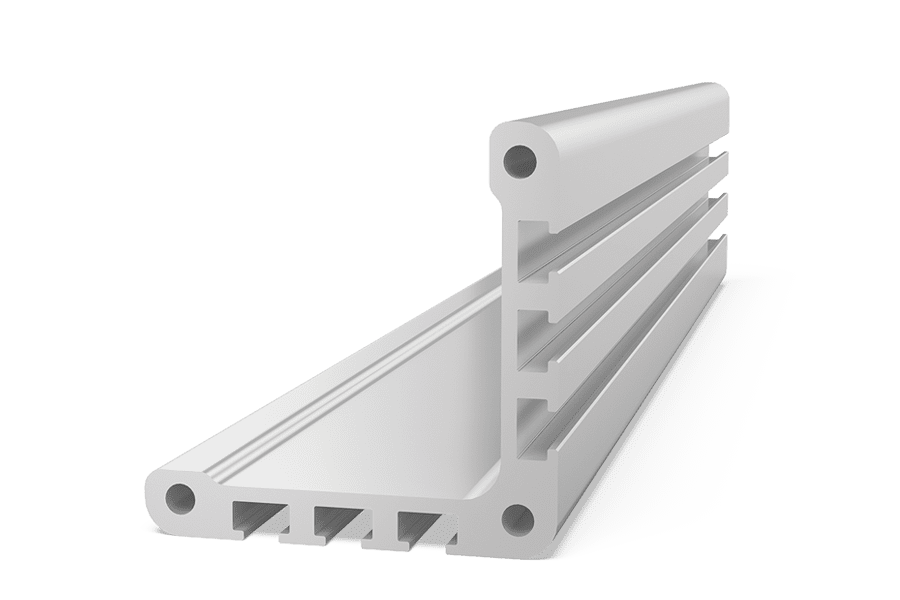

Aluminium Profiles

Adapter Plates

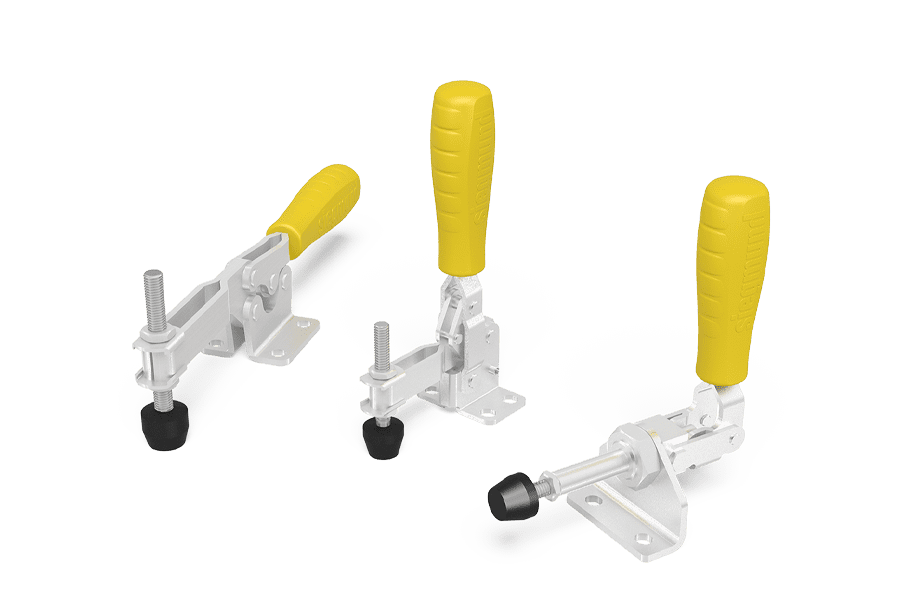

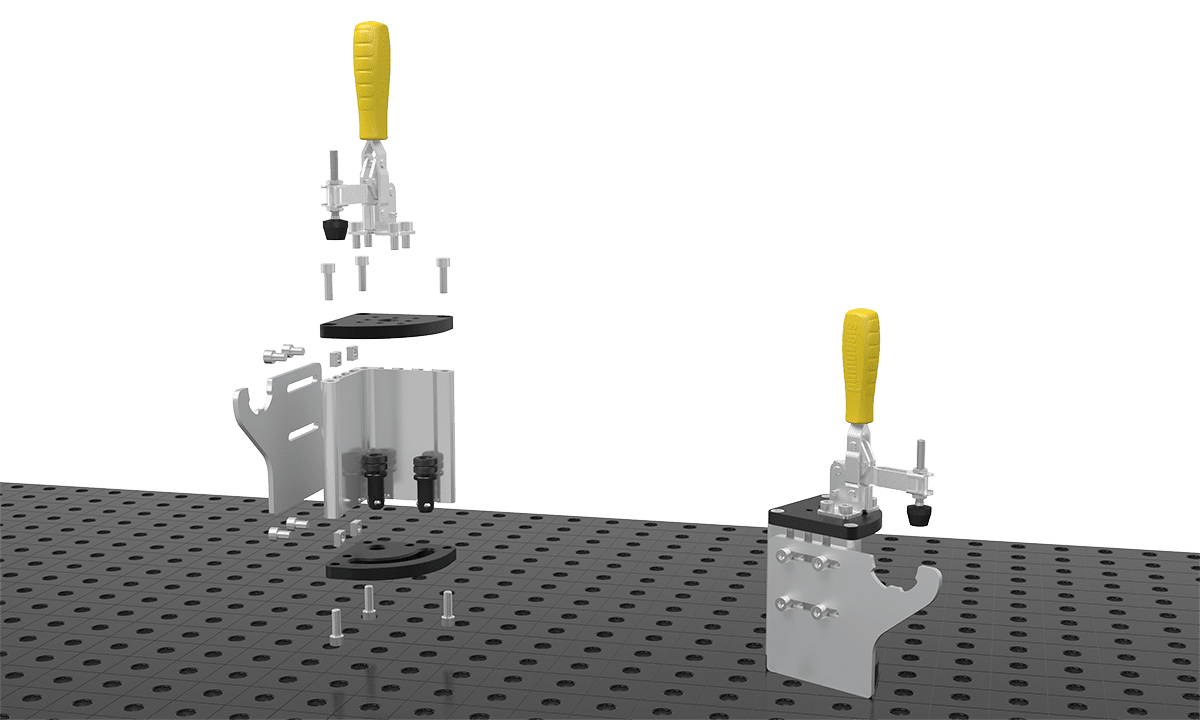

Quick Change Clamps

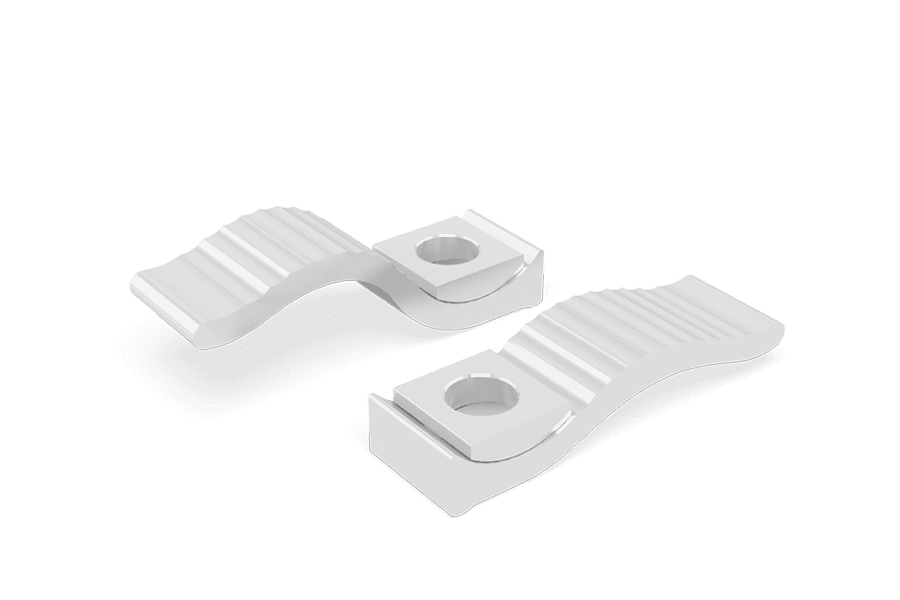

Clamping Claws

Starter Set

Assembly Instructions

𝟭. Define Square’s Height

- Cut the aluminum profile to the required length

- Note the minimum height of the cut

- Ensure cut edges are square

- Deburr the profile after sawing

𝟮. Fasten Base Plate

- Fasten aluminum profile using self tapping screws

- When the screws are screwed in, a thread is created in the profile

- Thread cutting is not required with self tapping screws

- Maximum torque: 20 kN

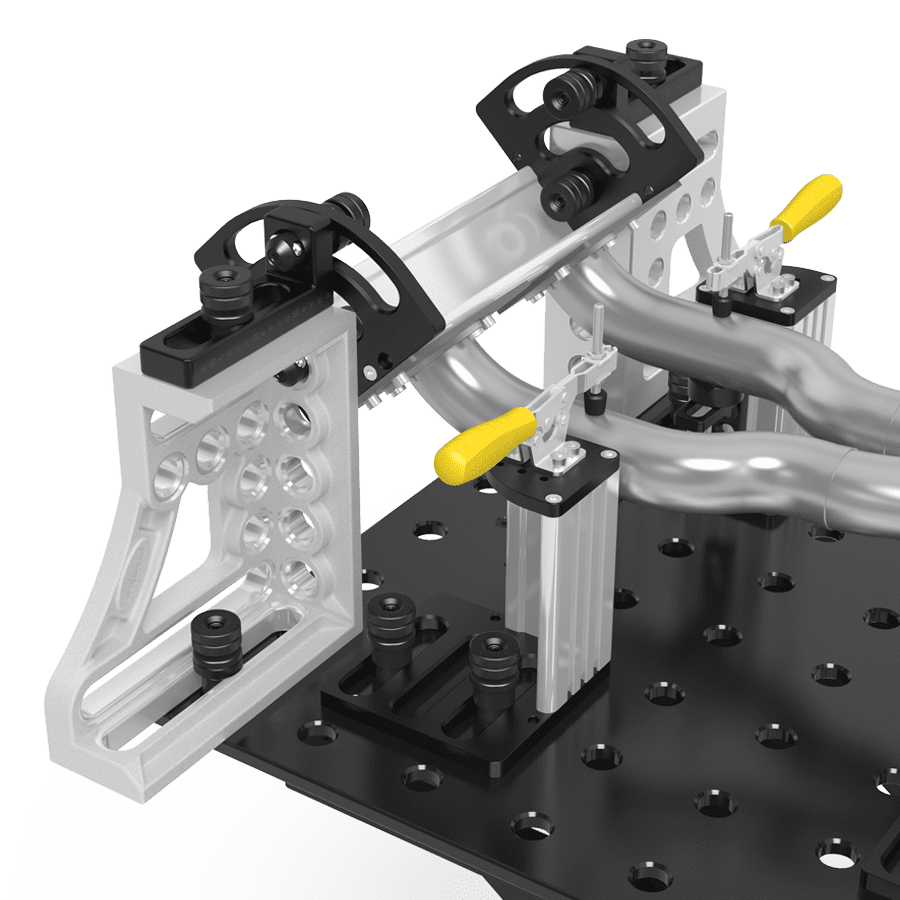

𝟯. Insert Square Nuts

- Insert square nuts in the T-Slot of the aluminum profiles

- For fastening customer side templates (material thickness 5 – 6 mm) or optionally also lateral fastening of quick change clamps with M8x12 screws

𝟰. Fasten Cover Plate

- Fasten aluminum profile using self tapping screws

- When the screws are screwed in, a thread is created in the profile

- Thread cutting is not required with self tapping screws

- Maximum torque: 20 kN

𝟱. Mount Accessories

- Mount the quick change clamp directly on the cover plate

- The quick change clamp can also be attached using an adapter

- Fastening of clamps, squares, stops and prisms in system 16 boreholes possible

𝟲. Clamp Devices

- Attachment to perforated plate, welding table or slot table with fast clamping bolts

- If required, use a M8x12 screw to fasten the customised template to a square nut

Video Instructions

Suitable Products

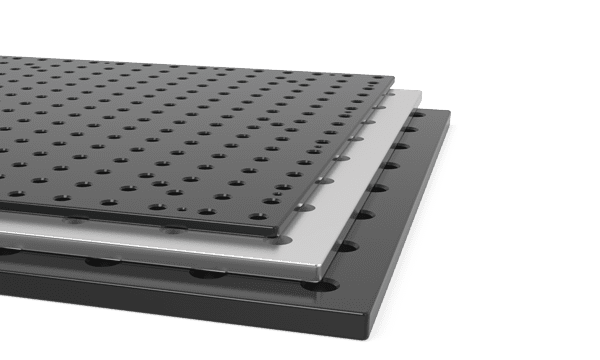

Perforated Plates

Our high load work plates are tailored to your needs, whether for sawing, drilling, welding or clamping. Made from S355J2+N steel or X8.7 tool steel, they’re plasma nitrided and BAR coated for durability.